Description

SHB 3 | Version 1.02

9

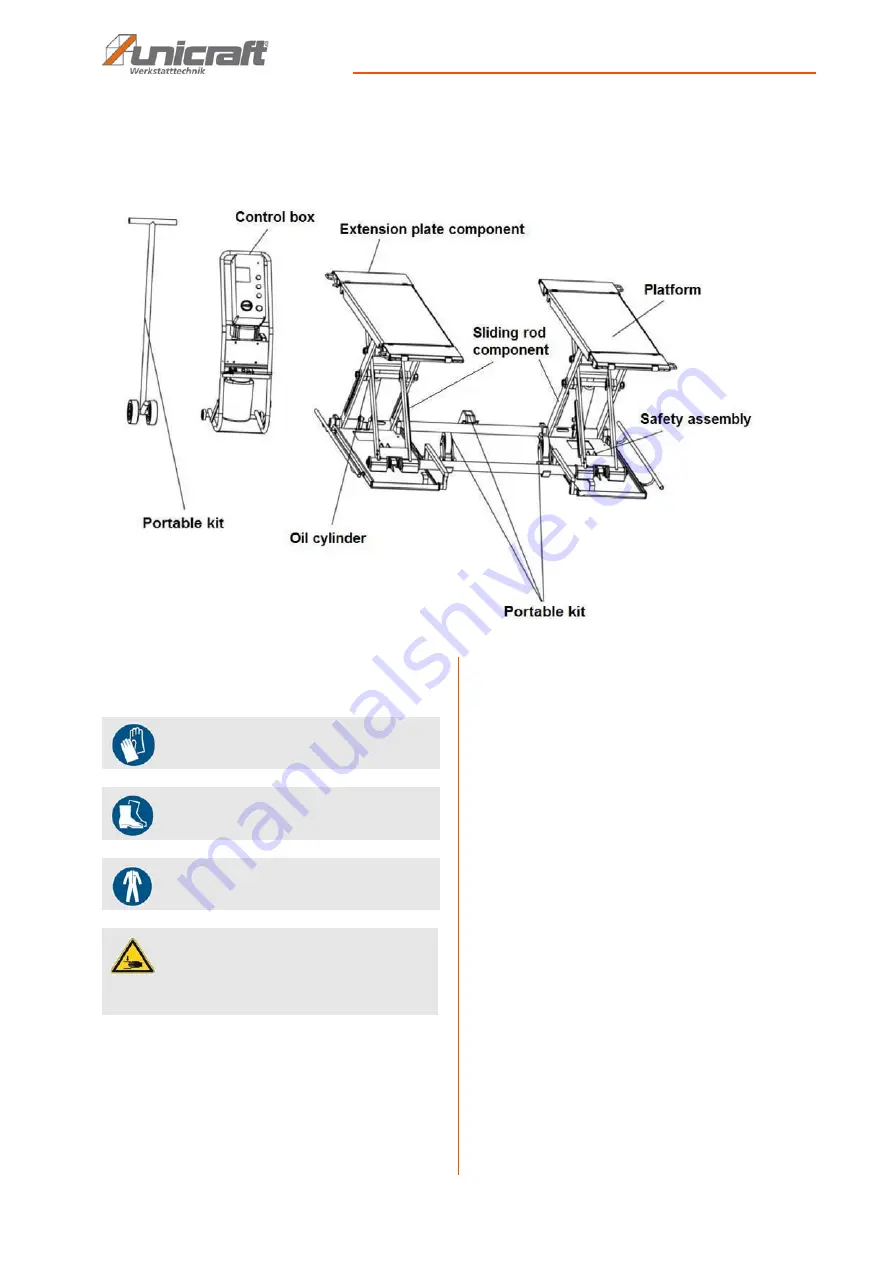

6 Description

Illustrations in this operating manual may differ from the original.

Fig. 6: Description

7 Assembly

The following tools are required for assembly:

- Electric drill

- Wrench

- Screwdriver

- Hammer

- Spirit level

7.1 Requirements for the installation site

The lifting platform must be set up on a level and solid

base. It must be ensured that there is sufficient freedom

of movement for working. The installation site should

meet the following criteria:

- The substrate must be level, solid and vibration-

free with a compressive strength of more than 3kg /

mm², a difference in level of less than 5 mm and a

minimum thickness of 200 mm (Fig.7). This thick-

ness is required for fixing with the ground anchors.

- The substrate must not allow lubricants to pass th-

rough.

- The installation or working area must be dry and

well ventilated.

- There must be sufficient space for the operating

personnel, for adjustment and maintenance work.

- The installation site must have good lighting.

- A new concrete floor must be dry for at least 28

days before the lift can be installed.

Use protective gloves!

Use protective boots!

Use Protective clothes!

CAUTION!

Risk of crushing!

There is a risk of injury to upper limbs when working

improperly on the scissor lift.

Содержание SHB 3

Страница 1: ...SHB 3 SHB 3 Instruction Manual Scissor lift SHB 3...

Страница 21: ...Notes SHB 3 Version 1 02 21 19 Notes...

Страница 22: ...www unicraft de...