1

1)

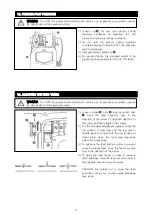

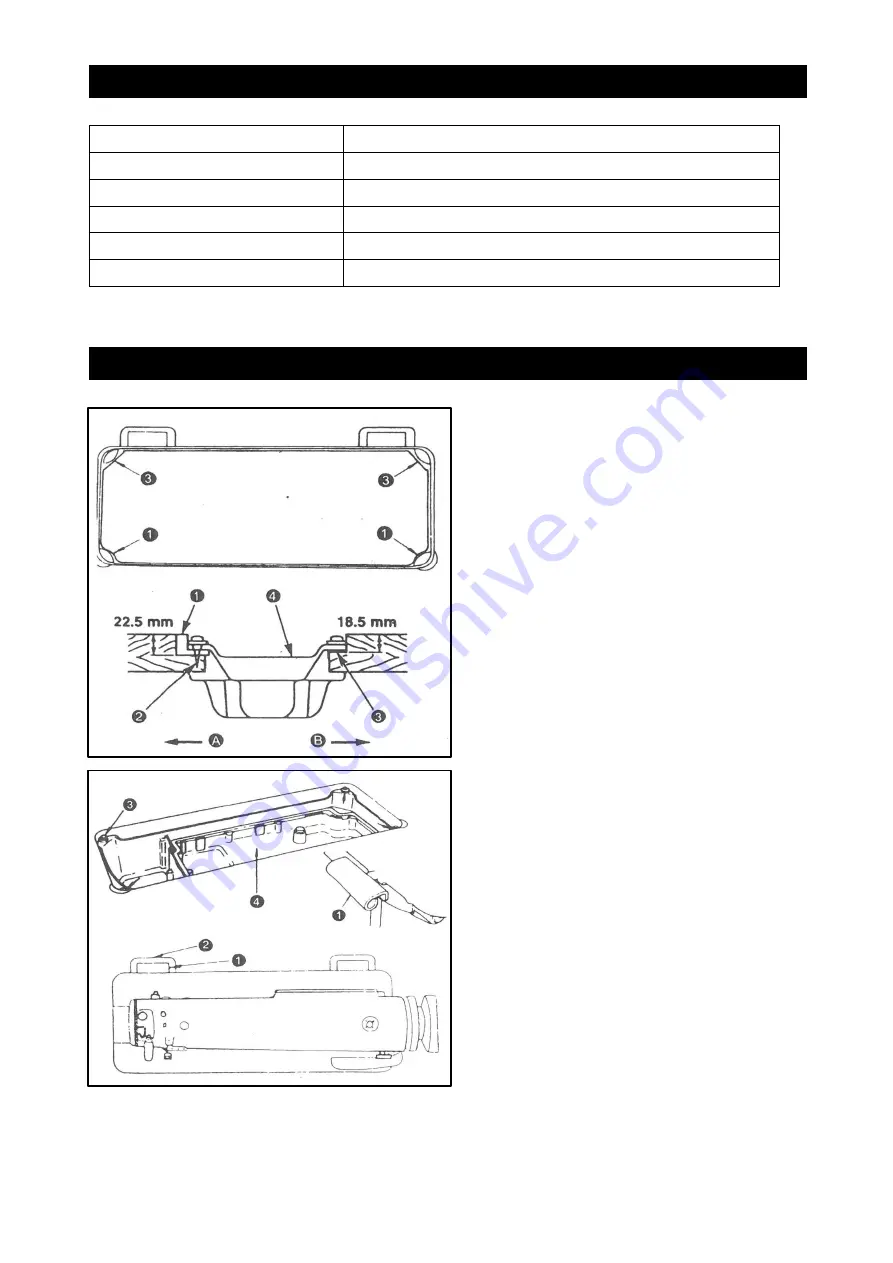

The oil pan should rest on the four corners of

the machine table groove.

2)

Fix two rubber seats

➊

on side

Ⓐ

(operator’

s side) using nails

➋

as illustrated above. Fix

two cushion seats

➌

on side

Ⓑ

(hinged side)

using a rubber-based adhesive. Then place

oil pan

➍

on the fixed seats.

3)

Fit hinge

➊

into the opening in the machine

bed, and fit the machine head to table rubber

hinge

➋

before placing the machine head on

cushions

➌

on the four corners.

Model

H5600-D

Application

Light-weight materials and medium-heavy weight materials

Sewing speed

Max. 4,500 rpm

Stitch length

4 mm

Presser foot lift (by knee lifter)

4.5mm (standard) 13mm (max.)

Needle

DB x 1 #9~#18

1. SPECIFICATIONS

2. INSTALLATION

Содержание H5600-D

Страница 1: ......

Страница 16: ...12 19 ATTACHING THE CLOTH CUTTING KNIFE 20 CHANGING THE CUTTING WIDTH...

Страница 17: ...13 21 ADJUSTING THE KNIFE COMPONENTS 22 ADJUSTING THE HEIGHT OF THE KNEE LIFTER...

Страница 18: ...14 23 OTHER REPLACEMENT PARTS...

Страница 19: ...15 24 WINDING THE LOWER THREAD 25 INSTALLING THE THREAD STAND...

Страница 20: ...16 26 ATTACHING THE WASTE CLOTH GUIDE...

Страница 21: ......

Страница 22: ...1 1 Machine Frame Miscellaneous Cover Mechanism 1...

Страница 24: ...3 1 Machine Frame Miscellaneous Cover Mechanism 2...

Страница 26: ...5 2 Main Shaft Thread Take up Lever Mechanism 1...

Страница 28: ...7 2 Main Shaft Thread Take up Lever Mechanism 2...

Страница 30: ...9 3 Needle Bar Vertical Shaft Hook Driving Shaft Mechanism...

Страница 32: ...11 4 Hand Lifter Mechanism...

Страница 34: ...13 5 Feed Mechanism 1...

Страница 36: ...15 5 Feed Mechanism 2...

Страница 38: ...17 6 Thread Trimmer Mechanism...

Страница 40: ...19 7 Automatic Reverse Feed Mechanism...

Страница 42: ...21 8 Oil Lubrication Mechanism Bobbin Mechanism...

Страница 44: ...23 9 Oil Pan Mechanism...

Страница 49: ......