40

Instructions for the installer

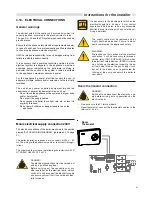

MINIMUM OUTPUT

ADJUSTMENT SCREW

3.23 - BURNER PRESSURE ADJUSTMENT

PK150X 2S

WARNING!

All the instructions indicated below are for the

exclusive use of qualified UNICAL service tech-

nicians or installers.

All the boilers are supplied already calibrated

and tested. However, if it is necessary to change

the calibration, the gas valve must be re-calibra-

ted.

Warning: during this operation do not request any

DHW draw-off .

B) Min output adjustment

-

Via the e-bus controller change the "Test" mode and run

the boiler at minimum output (refer to procedure illustra-

ted on page 43).

-

Check that the C02 values are within the values indica-

ted in the table "Burner pressures"

-

If necessary correct the value by turning the adjustment

screw "B" in a CLOCKWISE direction to increase the value

and in an ANTICLOCKWISE direction in order to decrea-

se it.

MAXIMUM OUTPUT ADJU-

STMENT SCREW

A) Max output adjustment

-

Remove the sampling point cap and insert a suitable C02

gas analyser in the flue outlet terminal.

-

Via the e-bus controller activate the "Test" mode and run

the boiler at maximum output.

-

Check that the C02 values are within the values indica-

ted in the table "Burner pressures"

-

If necessary correct the value by turning the adjustment

screw "A" in a CLOCKWISE direction to decrease the va-

lue and in an ANTICLOCKWISE direction in order to incre-

ase it.

Flue sam-

pling point

Note: To disenable the "Test" mode press the left

key.

C)

COMPLETION OF THE BASIC

ADJUSTMENTS

-

Check the C02 values at the minimum and maximum

input.

-

If necessary make the required adjustments

To ensure correct operation the C02 values

have to be adjusted with extreme care respec-

ting the values indicated in the table.

-

Replace the protective cap on the sampling test point on

the flue outlet terminal.