19

Instructions for the installer

3.10 - GAS CONENCTION

DANGER!

The gas connection must be carried out only

by a qualified registered engineer who will

have to respect and comply to the regulations

in force and to the requirements indicated by

the local gas supplier. An incorrect installa-

tion could cause injury to persons, animals or

damage to property. The manufacturer shall

not be held liable for any injury and/or

damage.

Before installing the boiler it is recommended

to thoroughly clean all the supply piping in

order to remove any eventual residual grime

which could compromise the boiler's correct

functioning.

If you smell gas:

a.

Do not turn on or off electrical switches,

use the telephone or any other object which

can provoke sparks;

b.

Open all doors and windows in order to

allow fresh air to enter and purify the room;

c.

Close all gas cocks

d.

Contact a service engineer, qualified

installer or your gas supplier.

As a safety measure against gas leaks,

Unical recommends installing a surveillance

and protective system composed of a gas

leakage detector combined with an on-off

selenoid valve fitted on the gas supply line.

The gas supply pipe must have a section which is adequate

to the burner's output.

It is however important to comply with the specific standards

and requirements in force.

Before commissioning an internal gas distribution system

and therefore before connecting it to the gas meter, the

complete installation must be tested for gas soundness.

If any part of the system is concealed from view the gas

soundness test must be carried out before covering the

pipes.

Before connecting the pipework the system must be tested

with air or inert gas at a pressure of at least 100mbar.

Before commissioning the boiler ensure that the following

operations are carried out:

-

Open the gas meter cock and vent the air contained in

the piping and subsequently proceed to vent device by

device.

-

Check, with the gas cock turned off, that there are no gas

leaks. During the 2nd quarter of the hour from the start of

the test, no pressure drop should be detected by the

pressure gauge. Any gas leaks must be found by using

only water soap solutions, or an equivalent product, and

eliminated.

-

Never look for gas leaks using a naked flame.

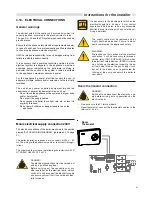

1

2

3

4

5

6

6

1 On-off gas supply valve

2 Double membrane regulator

3 Gas Filter

EXAMPLE OF A GAS SUPPLY SYSTEM

4 Anti-vibrating joint

5 Selenoid valve

6 On-off cock