Unibor E50 FRV Manual

Original Instructions

Nov 2019

21

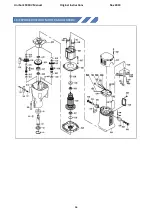

19) FITTING THE CHUCK

▪

The machine comes supplied with an RDC4087 (Arbor Shank) & RDC4084 (

1/2”

Chuck).

▪

Insert RDC4087 into RDC4009 (Arbor Spindle), ensure a good and tight fit is

achieved.

▪

Insert RD4084 into RDC4087, ensure a good and tight fit is achieved.

▪

Replacing the chuck is the reverse sequence, by utilising RDC4086 (Drift).

20) MAINTENANCE

In order to ‘get the best life’ out of your

Unibor machine always keep it in good

working order.

A number of items must always be checked on Unibor machines.

Always before starting any job make sure the machine is in good working order and that

there are no damaged or loose parts. Any loose parts must be tightened.

Before proceeding with any maintenance work be certain that the power supply is

disconnected.

Description

Every operation

1 week

1 Month

Visual check of

machine for damage

X

Operation of machine

X

Check brush wear

X

Check magnetic base

X

Check alignment of

the machine

X

Check grease

X

Check armature

X

Visually check the machine for damage.

The machine must be checked before operation for any signs of damage that will affect the

operation of the machine. Particular notice must be taken to the mains cable, if the machine

appears to be damaged it should not be used, failure to do so may cause injury or death.

Check operation of the machine.

The machines operation must be checked to ensure that all components are working

correctly.

Machine Brushes

Should be checked to make sure there is no abnormal wear present (this should be checked

at least once a week if used frequently). If the brush has worn more than 2/3 of the original

length, the brushes should be changed. Failure to do so may cause damage to the machine.