17

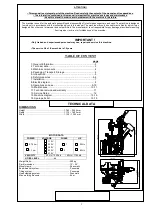

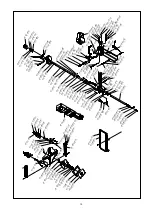

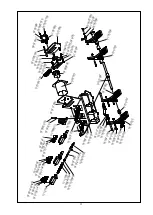

SPARE PARTS LIST

Number

CODE

DESCRIPTION

73

01 0013 0650

V

– BELT

74

72 00 001

MOTOR PULLEY GROUP

75

01 0115 008

NUT

76

01 0062 025

BOLT

77

01 0139 022

MILE SEGMENT

78

01 0082 025

BOLT

79

01 0052 107

TYRE CHANGER BEAD BREAKER

RUBBER

80

01 0031 37

ARM PULLING SPRING

81

01 0117 016

NUT

82

11 00 006

BEAD BREAKER PULLING METAL

83

11 00 005

BEAD BREAKER CONNECT PIN

84

47 30 000

BEAD BREAKER GROUP

85

01 0014 91-M

QUICK CAPLIN RECORD MALE

86

01 0014 54

RECORD

87

01 0198 13.5

PLASTIC CABLE RECORD

88

01 0014 99-PL

RECORD

89

01 0014 207

RECORD

90

11 00 020

NUT

91

11 00 019

REDUCTION

92

01 0014 80

SLEEVE

93

01 0014 15

RECORD

94

43 00 011

BEAD BREAKER CYLINDER CONNECT BOLT

95

01 0550 01

BEAD BREAKER CYLINDER GROUP

96

01 0063 030

BOLT

97

01 0139 014

MILE SEGMENT

98

48 01 010

PISTON CONNECTION MILE

99

01 0139 018

MILE SEGMENT

100

01 0139 012

MILE SEGMENT

101

01 0139 040

MILE SEGMENT

102

01 0031 136

BACK STRECHING METAL PUSHING SPRING

103

91 00 013

STRECHING METAL GAUGE PIN

104

01 0014 269

NIPPEL

105

91 00 002

STRECH MOVEMENT METAL SHEET

106

91 00 011

HOSE WAY PIPE

107

01 0031 32

BACK STRECH SPRING

108

01 0124 040

SETSCREW

109

01 0014 01

RECORD

110

01 0014 138

RECORD

111

01 0063 040

BOLT

112

01 0117 010

NUT

113

01 0130 040-50-1

RAYNEL WASHER

114

01 0117 018-1.5

NUT

115

01 0115 018

NUT

116

01 0112 18

WASHER

117

80 00 012

PILLAR SLIDING MILE

118

91 00 007

TYRE MOUNTING ARM STRECTHING METAL

119

59 09 000

BACK STRECHING CYLINDER GROUP

120

11 16 000

STRECHING CYLINDER GROUP

121

91 00 005

SLIDING REEL MILE

122

91 00 004

SQUARE SLIDING REEL

123

91 00 006

FRONT STRECHING MILE

124

11 00 003

MOTOR CONNECT METAL SHEET

125

01 0063 170

BOLT

126

01 0112 10

WASHER

127

01 0063 200

BOLT

128

01 0086 080

BOLT

129

01 0029 14 (DAMING)

BRAVA REDUCTION

130

01 0073 016

BOLT

131

91 00 012

HEAD REMOVAL CYLINDER LOWER CONNECTION MILE

132

91 00 020

UPPER BIG ABS

133

91 00 018

PILLAR UPPER ABS

134

11TI 23 000

AIR DISTRIBUTOR GROUP

135

91 05 000

PEDAL GROUP

136

01 0550 06

HEAD REMOVAL CYLINDER

137

91 05 001

PEDAL BODY GROUP

138

91 05 002

HEAD BREAKING AND FLANGE PEDAL GROUP

139

91 05 003

BEAD BREAKER PEDAL GROUP

140

91 05 004

POWER SWITCH PEDAL GROUP

141

91 05 007

PEDAL CONNECTION MILE

142

91 05 010

PEDAL INTERMEDIATE METAL BIG

143

91 05 011

PEDAL INTERMEDIATE METAL SMALL

144

91 05 018

BEAD BREAKER VALVE GROUP

145

91 05 017

FLANGE CYLINDER VALVE GROUP

146

91 05 016

HEAD REMOVAL CYLINDER VALVE GROUP

147

01 0072 025

BOLT