Ver. 01NL okt19

18

MAKERS LAB

Benno Premselahuis

Rhijnspoorplein 1

1091 GC Amsterdam

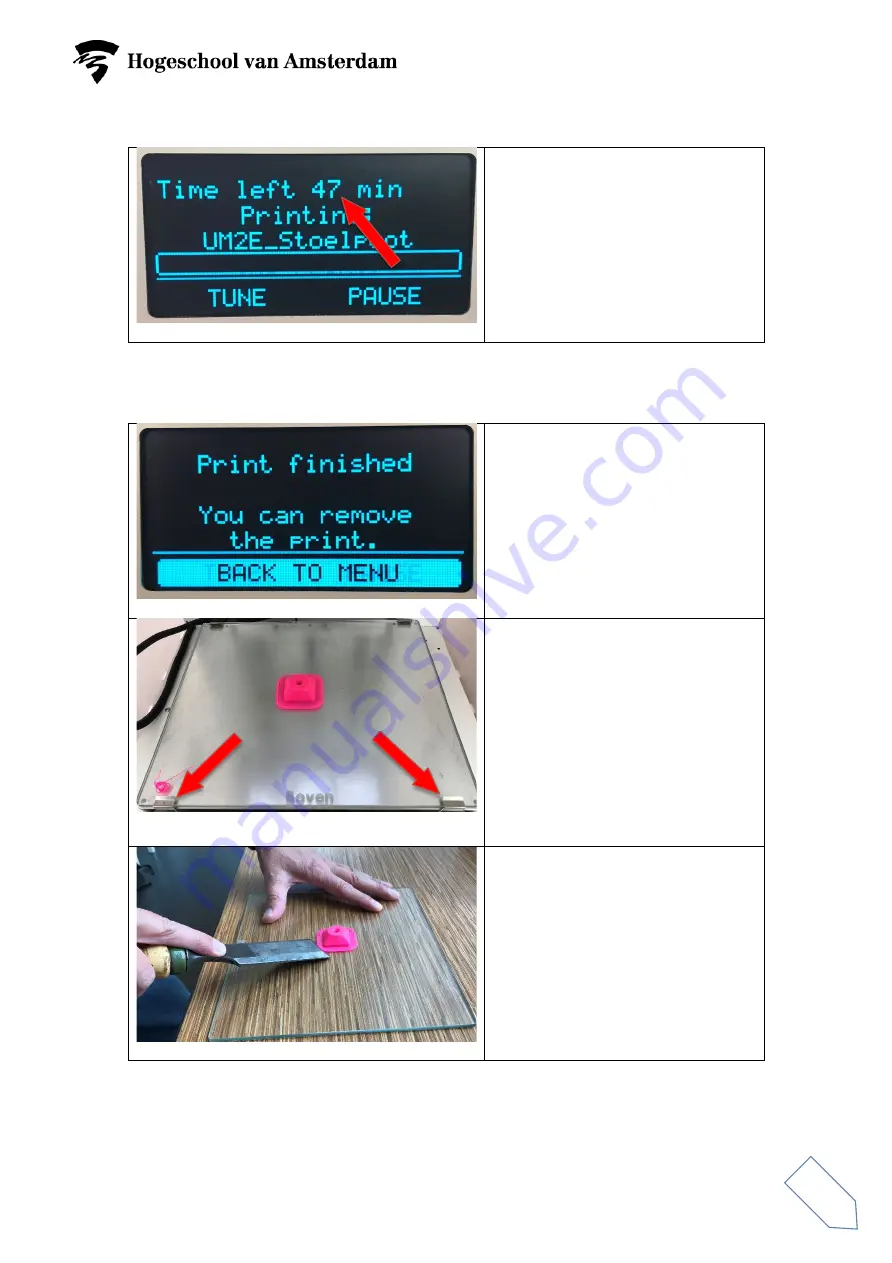

The print time displayed on the

screen is incorrect. The value found

in Cura will be reasonably accurate.

3D print ready

Let the printer cool down for at least

three minutes before attempting to

remove the glass plate from the

printer.

Open the two clips on the front of

the build plate. Twist them

completely open.

Slide the glass plate to the front and

remove it from the printer.

A note of caution:

Make sure not

to exert any pressure on the build

plate during this process.

Wait until the glass plate has cooled

off entirely before removing the

print from the plate. Use a chisel to

remove it. Use the chisel to ease up

the model from all sides.

A note of caution:

Never remove a

print while the glass plate is still in

the printer.