7

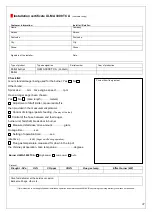

15. Auger pipe and T-pipe connected.

16. Push the auger pipe over the spiral and press on

and fix it in place with the outlet of the T-pipe towards

the side of the connector on the engine.

17. Fasten binding screw.

18. Assembled auger with hose mounted.

Boiler room & safety

There has to be an open air supply valve in the boiler room to give air to the combustion. The free surface of

the vent should correspond to the cross section area of the chimney. A hot air furnace can not get the hot air

from the boiler room! From a fire safety point of view it is important that the boiler room is clean and dust free.

Combustible materials should not be stored closer than 1,5m from the burner. Chemicals should not what so

ever be stored in the boiler room since they are often inflammable and can also cause risk of explosion. The

door to the boiler room should always be closed so that the room can work as a fire cell.

Pellet storage

The storage should be designed so that there are no unnecessary dust and chips at filling to avoid problems

like vaulting of the pellets. Therefore we recommend completed storages from MAFA i Ängelholm.

In cooperation with MAFA we can offer

two models of week storages that we

recommend MAFA MINI that holds 300

liters and MAFA MIDI that holds 700

liters. These storages are most suitable

when using pellets in small bags. For

houses and smaller real estates bulk

deliveries is the most comfortable,

effective and cheapest way to handle

fuel pellets. The pellet storage MAFA

VILLA is another intelligent home

storage for 3 tons bulk filling (the pellets

are blown in from a truck = comfortable).

Holds approx. 5.7 m3. Corresponds to

approx. six months consumption for a

normal home.

MAFA MINI week storage ( 300liter)

Содержание 3000 TCA

Страница 1: ...1 INSTALLATION AND MAINTENANCE OF ULMA 3000 TCA 30kW...

Страница 18: ...18 Wiring diagram...