106636-04 - 8/22

33

X-2

Installation, Operating & Service Manual

13

Service and Maintenance

(continued)

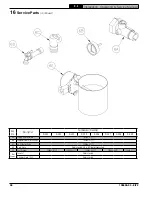

4. Clean Main Burners and Combustion Chamber.

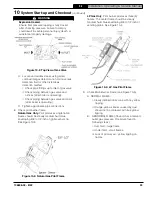

A. To remove burners for cleaning, changing

orifices, or repairs:

i. Remove Jacket Front Panel.

ii. Disconnect pilot tubing at gas valve.

iii. Disconnect 3-wire plug at the gas valve.

iv. Remove wires to flame roll-out switch.

v. Disconnect ignitor sensor cable at boiler

control.

vi. Remove burner access panel.

vii. Mark location of pilot main burner on the

manifold if marking on manifold is missing.

viii.Hold burner at throat. Lift front of burner

to clear orifice. Pilot burner can only be

removed by lifting the burner adjacent to its

right first.

B. Brush top of burners with a soft bristle brush.

Vacuum burners.

C. Check orifices. Drilled passageways must be

free of lint or dirt.

D. Vacuum tip of Pilot Burner.

E. Clean combustion chamber by vacuuming.

Exercise care not to damage base insulation.

F. Install burners by reversing procedure used

to remove burners. Make sure burner with

pilot assembly is in same location as original

installation.

WARNING

Be careful handling pilot tubing. Do not crimp

or crack pilot tube. Leaking pilot tubing could

result in serious injury, or substantial property

damage.

Check burners to see that they are located

properly in slot at rear of burner tray. Reinstall

burner access panel. Reconnect flame roll-out

switch wires, pilot gas supply, and pilot lead.

G. Connect pilot gas supply, igniter/sensor wire,

and ground wire at Boiler Control.

F. Install Burner Access Panel. Connect Flame

Rollout Switch wires.

5. Inspect Water Piping.

A. Check all system piping for leaks.

B. Repair any leaks before placing back into

service.

6. Inspect Temperature/Pressure Gauge.

A. Water temperature needle should move with

variation in water temperature.

B. Pressure needle should move with variation in

pressure.

C. Replace gauge if needed.

7. Operate Safety Relief Valve.

A. When manually operating relief valve,

water will discharge. Take precautions to

avoid contact with hot water and avoid water

damage. Inspect relief valve and lift lever to

verify flow.

B. If relief valve leaks or will not seat properly,

replace relief valve.

8. Inspect Gas Piping.

A. Sniff around boiler area for indication of gas

leak.

B. Locate leaks using approved gas detector,

a non corrosive leak detector fluid or other

approved leak detection methods.

C. Repair any leaks before placing back into

service and retest.

DANGER

Explosion Hazard.

Do not use matches, candles, open flames, or

other ignition sources to check for leaks. Failure

to comply could result in severe personal injury,

death, or substantial property damage.

9. Inspect Air Openings.

A. Keep boiler area clear of combustible

materials.

B. Remove any obstructions in boiler room

that will hinder flow of combustion and

ventilation air and dilution air.

10. Follow Section 10 instructions to put boiler back

into operation.

11. Check CO detector operation (if available).

12. Lubrication. There are no parts requiring

lubrication by service technician or owner.

Circulator bearings are water lubricated.

13. If remodeling has occurred, verify combustion air

supply is adequate.

!

!