USER GUIDE

R-600A Specifications 2

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE •

SERVICE

WARNING

!

Only skilled and well trained service technicians

permitted to service R-600a equipped products.

All tools and equipment must be approved for

use with R-600a refrigerant.

Local, state and federal laws, standards must be

observed along with proper certification and

licensing.

Ventilation is required during servicing.

No conversions to R-600a from any other

refrigerants. OEM R-600a equipped unit only.

Service area must be free of ignition sources.

No smoking is allowed in the service area.

All replacement electrical components must be

OEM and installed properly (sealed and

covered).

If the evaporator is cold prior to service, it must

be thawed prior to service.

When using a vacuum pump, start pump before

opening refrigeration system.

Vacuum pump and recovery equipment should

be at least 10 feet from the work area.

It is recommended that a simple LPG gas

detector is on site during service.

Ensure that all R-600a is removed from the

system prior to brazing any part of the sealed

system.

Only a clean, dry leak free system should be

charged with R-600a.

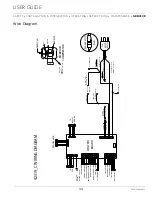

R-600A SPECIFICATIONS/LABELING

R-600a equipped products are labeled (both the unit and

the compressor).

R-600a is colorless and odorless.

R-600a is considered non-toxic, but is flammable when

mixed with air.

Do not remove or alter any R-600a labeling on the

product.

Use only a refrigerant grade R-600a from a properly

labeled container.

RECOVERING/RECLAIMING R-600A

(R-600a has been exempted from recovery/reclaiming

requirements by the US EPA)

Recovery/Reclaiming equipment must be approved for use

with R-600a.

Ensure the evaporator is at room temperature prior to

recovery/reclaiming R-600a.

Use a common piercing pliers or piercing valve to remove

R-600a from the compressor process tube. (Note: Piercing

devices must not be left on the system and must be

replaced with a Schrader type valve.)

39