4

Twin City Engineering Supplement 895

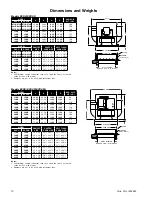

Table 2. TSL Wheel-Funnel Overlap

SIZE

402

445

490

542

600

660

730

807

890

A

40.25

44.50

49.00

54.25

60.00

66.00

73.00

80.75

89.00

B

1.03

1.13

1.25

1.38

1.56

1.69

1.88

2.09

2.28

C (CL 1)

16.23

17.92

19.64

21.70

24.08

26.42

29.19

32.30

35.66

C (CL 2)

16.23

17.92

19.64

21.70

24.08

26.42

29.19

32.30

35.66

C (CL 3)

16.30

17.98

19.70

21.83

24.14

26.48

29.25

32.36

35.70

SIZE

122

150

182

200

222

245

270

300

330

365

A

12.25

15.00

18.25

20.00

22.25

24.50

27.00

30.00

33.00

36.50

B

0.31

0.38

0.56

0.63

0.69

0.75

0.88

0.97

1.06

0.94

C (CL 1)

4.69

5.86

7.36

8.00

8.89

9.86

10.91

11.89

13.31

14.72

C (CL 2)

4.72

5.86

7.42

8.06

8.95

9.86

10.91

11.89

13.31

14.72

C (CL 3)

—

—

7.48

8.13

9.08

9.92

10.97

12.14

13.38

14.78

C

B

A

Note

: Use “B” dimension for positioning wheel.

Table 3. QSL Wheel-Funnel Overlap

B

A

C

Note

: Use “B” dimension for positioning wheel.

SIZE

150

165

182

200

222

245

270

300

330

A

18.25

20.00

22.25

24.50

27.00

30.00

33.00

36.50

40.25

B

0.56

0.63

0.69

0.75

0.88

0.97

1.06

0.94

1.03

C

6.19

6.75

7.56

8.31

9.13

10.19

11.19

12.38

13.63

SIZE

365

402

445

490

542

600

660

730

A

44.50

49.00

54.25

60.00

66.00

73.00

80.75

89.00

B

1.13

1.25

1.38

1.56

1.69

1.88

2.09

2.28

C

15.13

16.63

18.38

20.25

22.31

24.63

27.25

30.00

Operation Checklist

□

Verify that proper safety precautions have been

followed.

□

Electrical power must be locked off.

Check fan mechanism components:

□

Nuts, bolts, setscrews are tight.

□

Mounting connections are properly made and

tightened.

□

Bearings are properly lubricated.

□

Wheel, drives and fan surfaces are clean and

tightened.

□

Rotating assembly turns freely and does not rub.

□

Drives on correct shafts, properly aligned, and

properly tensioned.

Check fan electrical components:

□

Motor is wired for proper supply voltage.

□

Motor was properly sized for power of rotating

assembly.

□

Motor is properly grounded.

□

All leads are properly insulated.

Trial “bump”:

□

Turn on power just long enough to start assembly

rotating.

□

Check rotation for agreement with rotation arrow.

□

Listen for any unusual noise.

Run unit up to speed:

□

Bearing temperatures are acceptable (<200°F) after

one to two hours of operation.

□

Check for excess levels of vibration. Filter in readings

should be 0.15 inches per second or less.

After one week of operation:

□

Check all nuts, bolts and setscrews and tighten if

necessary.

□

Re-adjust drive tension if necessary.