4

Twin City IM 4205

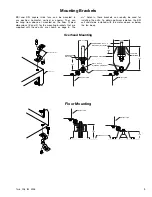

Figure 3. Low End Setpoint Adjustment

NOTE:

5 amp model shown. On 10 and 15

amp models, adjustment is made through clear-

ance hole in heat sink.

SETPOINT

ADJUSTMENT

SCREW

Table 4. Speed Controller Size

Speed Control Installation

(Model DSI - optional)

Speed control is available for DSI models using

115/60/1

open

type PSC or shaded pole motors.

Note:

If using an

EC motor

to vary the speed, you must

use IM-4055.

Installation

Connect control in series with motor and line voltage

(

115V only

). Never connect across line. See Figure 2.

Minimum Speed Setpoint

All controls are factory set to 65V±3V output as stan-

dard with an input voltage of 120V. If different minimum

speed is desired, the control may be adjusted by turn-

ing minimum speed pot clockwise to decrease minimum

speed and counterclockwise to increase minimum speed.

Refer to Figure 3.

Warning:

If minimum speed is readjusted, verify unit

ampere draw does not exceed motor nameplate amps.

Do not operate unit in range where amp draw exceeds

motor nameplate.

Caution:

These motors operate more efficiently in the

ranges set from the factory. Operating motor outside

these ranges (see Table 3) may cause motor to run

hotter and substantially shorten motor life.

Note:

Lowering the minimum speed setpoint may

adversely affect motor start-up characteristics.

Warning:

Certain failure modes of solid-state controls

such as half-waving can cause high levels of DC, motor

overheating and motor burn-out. Therefore, a thermal

overload protection (integral with motor) is required to

limit the maximum motor temperature under such a

failure.

Note:

Do not allow any sleeve bearing motor to operate

below 500 RPM. Operation below 500 RPM will sub-

stantially shorten bearing life.

Figure 2. Connection Diagram, Speed Control

SPEED CONTROLLER

AC

LINE

(115V)

SWITCH TRI-AC

MOTOR

Table 3. Speed Controller RPM Range

NOTES:

1. Speed control available

only

with 115/60/1 open motors (thermally

protected).

2. Three-speed motor (multiple tap winding).

3. Speed control

should not

be connected to low speed tap on motor

because of starting characteristics.

4. Speed control connected to high speed tap on motor.

5. Speed control connected to medium speed tap on motor.

HP

RPM

MAX. RPM

MIN. RPM

1/30

1650/1500/1350

2,3

1650

4

1300

4

1/8

1500

5

950

5

1/15

860

860

500

1/8

1/6

1/4

1/2

1/8

1140

1140

900

1/6

1/4

1/2

1

1/3

1725

1725

1200

1/2

3/4

MOTOR

SPEED CONTROLLER

DESIGNATION / FLA"

PART

NUMBER

ENCLO-

SURE

VOLT-

AGE

HP

RPM

KBWC-15K

5 AMP

KBWC-110

10 AMP

KBWC-115

15 AMP

66801400

Open

115V

1/30

1650/1500/

1350

X

66543600

Open

115V

1/8

1650/1500/

1350

X

66804500

Open

115V

1/15

860

X

66543700

Open

115V

1/8

860

X

67123100

Open

115V

1/6

860

X

66543800

Open

115V

1/4

860

X

66543900

Open

115V

1/2

860

X

66804600

Open

115V

1/8

1140

X

67125100

Open

115V

1/6

1140

X

66544000

Open

115V

1/4

1140

X

66544100

Open

115V

1/2

1140

X

66544200

Open

115V

1

1140

X

66544300

Open

115V

1/3

1725

X

66544400

Open

115V

1/2

1725

X

67122500

Open

115V

3/4

1725

X