6

C. DRUM SECTION

DISASSEMBLY

1. To remove the drum, first disconnect the cable

from the u-bolt (43) and lay aside. If removing

the drum from the motor end with the motor

and brake disassembled, first remove the

eight capscrews (51), eight roll pins (103), and

air cylinders covers (96,97) on the air cylinders

(17 & 125).

Note: you

may need to remove

the air lines. Mark them for re-assembly.

2. You will need to support the weight of the

drum with a hoist. Remove the four capscrews

(70) and the nuts and washers (71, 72) on the

bottom of the brake housing, (16). At this time

you will need to remove two capscrews (91),

nut and washers (85, 86) from the frames (73

or 74). Do not remove air cylinder (76) yet.

Disconnect the air line from the backside of

the brake housing (16) that goes to the band

brake cylinder. If a complete tear down is not

necessary, make sure the output shaft (20) or

input shaft (21) does not move during removal

of the drum. With help from a hoist or another

person, slide the whole brake housing out

from the drum until you are free of everything.

You can now remove the brake band

assembly (77). Note which frame the

mounting bolts are on for re-assembly.

Inspect and replace any worn parts of this

assembly. Remove the outer thrust collar

(131) by removing two set screws (130).

3.

Remove the thrust ring (128) and clutch plate

(15) by removing six capscrews (129).

Remove the sliding clutch (13), coupler (12),

keys (47) and the inner thrust collar (46).

Remove the drum using a hoist. Inspect the

bushings (19) in both ends of the drum.

Note:

You may also inspect the bushing and seal

(40, 41) that are located in the end of the

brake housing.

4.

Inspect or replace the drum clutch (14) at this

time by removing six capscrews (45). If you

replace the clutch, make sure to torque the

capscrews to the specified torque upon re-

assembly.

D. GEAR SECTION

DISASSEMBLY

1. Drain the oil at the bottom of the gear housing

by removing the plug (31).

2. To disassemble the gear section, you must

start with the outer cover. Remove the

capscrews (30) and cover (3A).

Note: If you

have the blocked piston cover assembly, take

it off as an assembly and see Service of

Blocked Piston Cover Assembly.

3. Inspect the o-ring (33), bearing (27), and

spacer (127). Remove and inspect the outer

thrust washer (34) and replace if necessary.

4. Remove input gear set (22A), the inner thrust

washer (34), sun gear (7), and the secondary

gear set (23). Remove the thrust washer (37)

and inspect for wear. Replace if necessary.

5.

Remove the primary housing (9) by removing

eight capscrews (35).

Note: The housing is

very heavy. Use caution when removing it.

6. After removing the primary housing, inspect

the o-ring (36). Remove the sun gears (8

,111). Rotate thrust washer ((24-5) or (24-7))

into alignment with snap ring ((24-9) or (24-8)).

Remove snap ring from groove on shaft (20).

Remove output gear set (24). Remove and

inspect the thrust washer (38). Replace if

necessary.

E. PLANET SET DISASSEMBLY

1. Remove the retaining rings from the planet

pins.

2. Remove the pins from the carrier by carefully

tapping them out.

3. Remove the planet gears, thrust washers and

bearings from the carriers.

4. Inspect the pins, bearings, and gear bores for

evidence of wear and replace if necessary.

5. To

re-assemble

output gear set first insert

snap ring.

6. Next insert thrust plate into carrier of input or

output gear set along with gears, bearings and

washers.

7. Being careful to line up the planet pins with the

thrust washers and bearings. Press the pin

into the carrier. If the pins are not lined up

properly, the thrust washer can be shattered

during the pressing operation.

8. Replace retaining rings.

Содержание Rufnek 100

Страница 7: ...7...

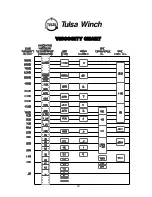

Страница 20: ...19 VISCOSITY CHART...

Страница 22: ...21 TWG PO Box 1130 Jenks OK 74037 1130 USA Phone 918 298 8300 www dovertwg com...