5

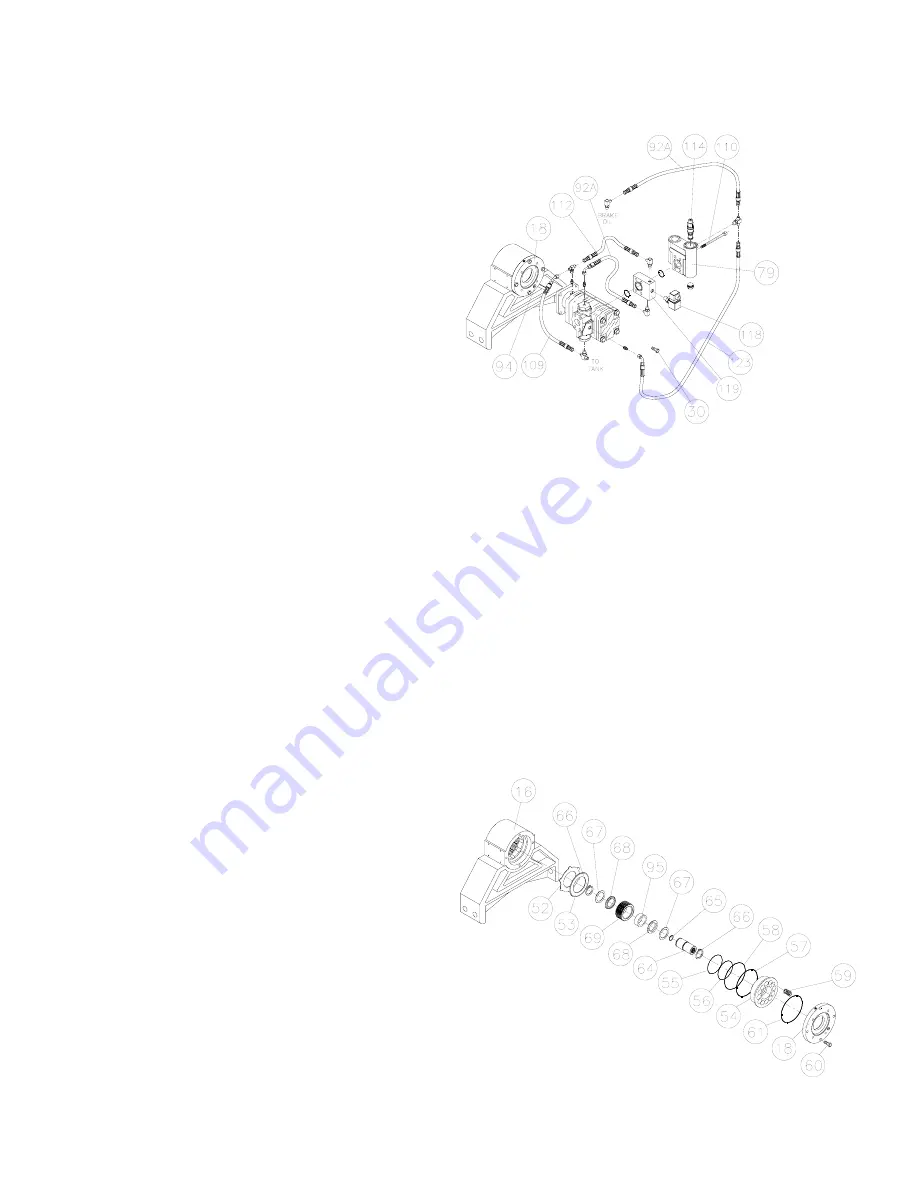

GENERAL DISASSEMBLY

A. MOTOR DISASSEMBLY

1. Drain the oil from the brake assembly by

removing the plug (94) from brake cover (18).

2. Remove hoses (92A, 109 & 112).

3. Remove the counterbalance block (79);

manifold block (119) and switch (118) from the

motor by removing the four capscrews (110).

4. Remove the counterbalance valve (114) from

the counterbalance block (79) and inspect the

metering hole to make sure it is not

obstructed. Also, inspect the o-rings to insure

that they are not flat or cut. Replace if

necessary.

5. Motors and counterbalance valves are not

serviceable in the field. Return them to an

authorized dealer for service.

B. BRAKE SECTION

DISASSEMBLY

1. Evenly remove the four capscrews (60) that

hold the brake cover in place. Spring pressure

will raise the cover up as the capscrews are

loosened. Carefully remove the cover (18)

from the brake housing (16). Inspect the o-ring

(61) for damage.

2. Remove the springs (59) from the piston (54)

and check the free height. Each spring should

measure at least 1.200 inches with no force on

them.

3. Remove the piston (54) by installing two

pieces of 3/8”-16NC all thread into the two

holes in the top of the piston and run in evenly

until the piston is clear of the housing. An

alternate way of removing the piston is to use

a portable hydraulic power unit or air to gently

pressurize the brake cavity to remove the

piston from the brake housing (16).

4. Inspect o-rings (55, 57) and back up rings (56,

58) on the piston. Replace if necessary.

Grasp the brake driver/clutch assembly

(assembled items 64, 65, 66, 67, 68, 69, 95)

and remove it from the brake housing.

5. Remove the stator plates (52) and friction

discs (53) from the brake housing and check

them for excessive wear. Replace if

necessary. Be sure to check the top stator

plate for scoring caused by the removal of the

piston and polish if necessary. Friction discs

should measure no less than .055-in.

thickness and stator plates should measure no

less than .068-in thickness.

6. To disassemble the brake driver/clutch

assembly, remove the retaining ring (66) from

either end of the driver. Then remove the race

(67) and bushing (68). Slide the brake driver

off the drive coupling.

(Note:

Notice the

direction of lock-up on the clutch for re-

assembly).

Inspect the driver coupling and

brake driver for wear. Replace if necessary. If

the drum bushings or seals need to be

replaced, see the drum section of this manual

before re-assembly of the brake.

Содержание Rufnek 100

Страница 7: ...7...

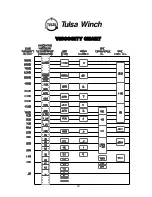

Страница 20: ...19 VISCOSITY CHART...

Страница 22: ...21 TWG PO Box 1130 Jenks OK 74037 1130 USA Phone 918 298 8300 www dovertwg com...