12

PROCESSOR MAINTENANCE

Regular maintenance is the key to long equipment life and safe operation. It is very

important that these maintenance functions be performed as described below.

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS

(pages 3-6 of this manual)

BEFORE BEGINNING ANY PROCESSOR MANTENANCE OPERATION

IMPORTANT

The flail tube on this machine is a fully balanced assembly. If for any reason the flails must be removed,

they must be returned

to the

same position

they were taken from. If this is not done a balance problem

will result in causing machine vibration. Number flails and inserts and their positions before you do any

work.

BEFORE FIRST USE

Inspect the attachment for shipping damage. If damage does exist, do not operate until the damaged parts

have been replaced or repaired.

BEFORE EACH USE

Check for loose or badly worn parts.

Conveyor chain should be adjusted to allow chain slack 1” (2.54 cm) to 1½” (3.8 cm).

Make sure that all hydraulic fittings are tightened and that there are no leaks in any fittings or hoses.

Inspect rotor and all rotating parts for twine or wire build-up.

Check for cylinder wear and broken flails and flail bracket wear. Replace with new “

Boss

” flails to keep

machine in balance.

Make sure that all safety signs are in place, are clean and are legible.

SEE THE SAFETY SIGN SECTION

(page 6)

AFTER EVERY 10 HOURS OF OPERATION

Grease all roller bearings. (

refer to diagram on page 10)

Inspect and tighten Allen screws on bearing.

PROCESSOR SERVICE

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS

(

pages 3-6 of this manual)

BEFORE BEGINNING ANY PROCESSOR SERVICE.

WARNING

Hydraulic fluid under pressure can penetrate skin, resulting in serious injury or death.

Always relieve hydraulic pressure before disconnecting lines.

Shut off engine, set parking brake and relieve hydraulic pressure before connecting or

disconnecting hydraulic lines. Refer to your power unit’s manual for instruction on how to

relieve hydraulic pressure in lines.

Before applying pressure to the system, be sure that all connections are tight and be sure there

are no damaged hoses, lines or fittings.

Wear safety glasses and use metal or wood when searching for leaks. Do not use your hands.

WARNING

Before servicing the loader, remove the attachment

and make certain the lift arms are lowered to their lowest position

or that the arms are supported by the mechanical lock up devices (if the machine is so equipped).

Steam-clean the power unit before any installation is made to the hydraulic system.

Remove any attachment from the power unit and position on a level surface.

Содержание Boss I

Страница 1: ...Operator s Manual Tube Line Bale Processor Boss I ...

Страница 2: ......

Страница 9: ...9 ...

Страница 13: ...13 ...

Страница 14: ...14 ...

Страница 15: ...15 ...

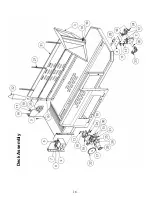

Страница 16: ...16 Deck Assembly ...

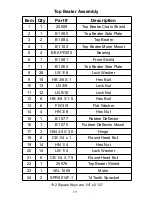

Страница 18: ...18 Top Beater Assembly ...

Страница 20: ...20 Bottom Beater Assembly ...

Страница 22: ...22 Hydraulic Layout 1 2 3 4 5 6 7 8 9 ...

Страница 24: ...24 Optional 3 rd Beater Kit ...

Страница 26: ...26 ...

Страница 27: ...27 ...

Страница 28: ...28 ...