SWITCHING OFF

1)

Leave the shredder to empty itself for a few minutes to eliminate residual

material from behind the feed roller and inside the shredder, which could

jam the rotor when the machine is next started up.

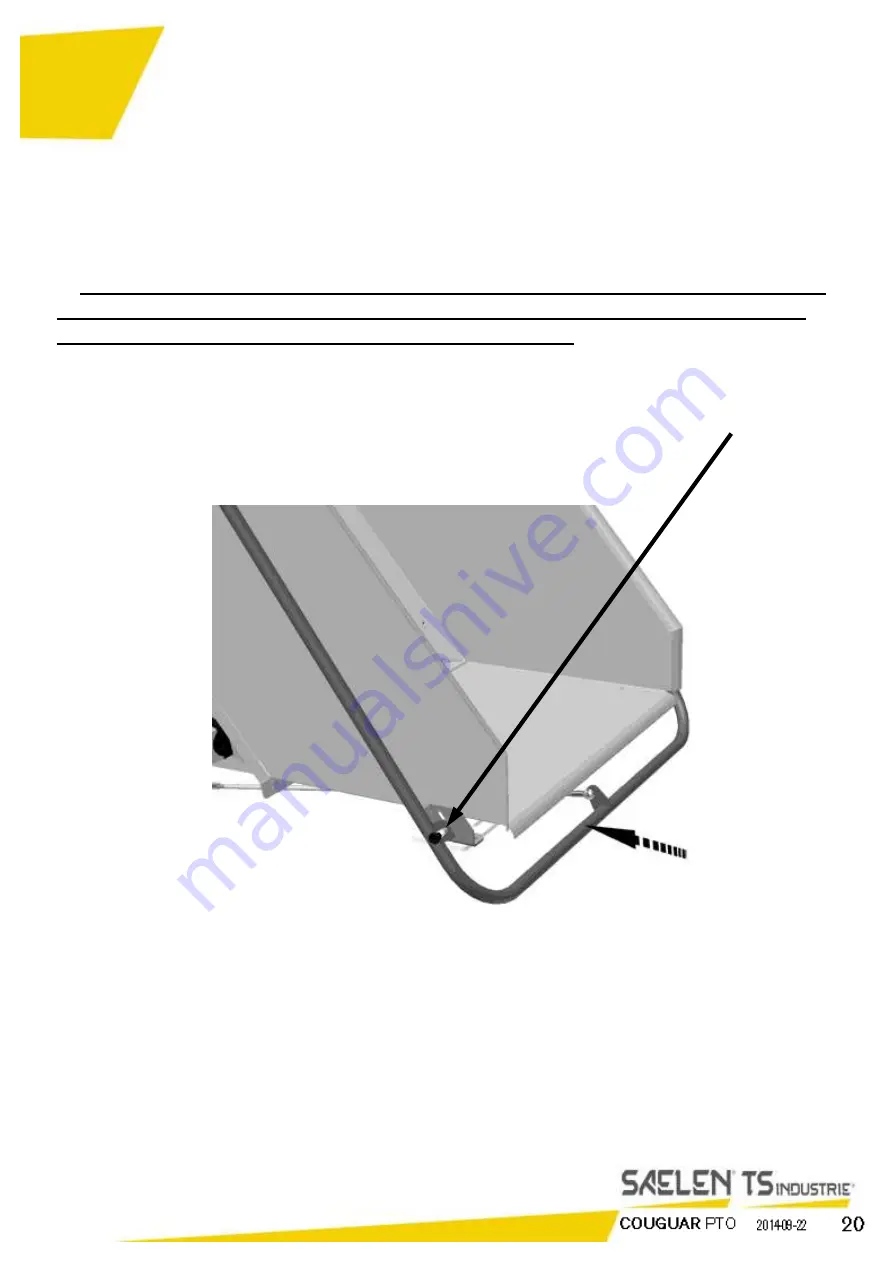

2) Push the control bar forward to stop the feed roller so what is locked by the finger

indexing

3) Progressively return the throttle handle to idle.

4) Disengage the tractor.

O P E R A T I N G

P R O C E D U R E S

Содержание Saelen GS/COUGAR PTO

Страница 1: ...TECHNICAL MANUAL...

Страница 2: ...MAJ 09 2008...

Страница 34: ......

Страница 35: ......

Страница 36: ...CONNECTION OF THE HYDRAULIC HOSES HYDRAULIC COUPLING...

Страница 38: ......