6

© TrynEx International 2013 (REV A) F51073A

Operating Instructions

Spreading Tips

The application rate, which is the amount of material spread on a given area, depends on three variables – Vehicle Speed, Spinner Speed and

Auger Speed.

For consistency in spreading results, it is best to drive at a constant speed.

The Spinner Speed changes the spread width. This determines how much area the same material fed by the auger will cover.

Auger Speed changes how much material is fed to the spinner. Changing this will change the amount of material being spread in the same

area.

Wider Spread Patterns will spread the same material over a larger area, so the application rate will be decreased unless you increase your

Auger Speed or drive slower. A Narrower Spread Pattern requires the opposite action: a slower Auger Speed or drive faster.

To maintain your application rate with a wider spread pattern, you can increase your auger speed, drive slower, or spread the area twice.

To maintain your application rate with a narrower spread pattern, you can decrease your auger speed or drive faster.

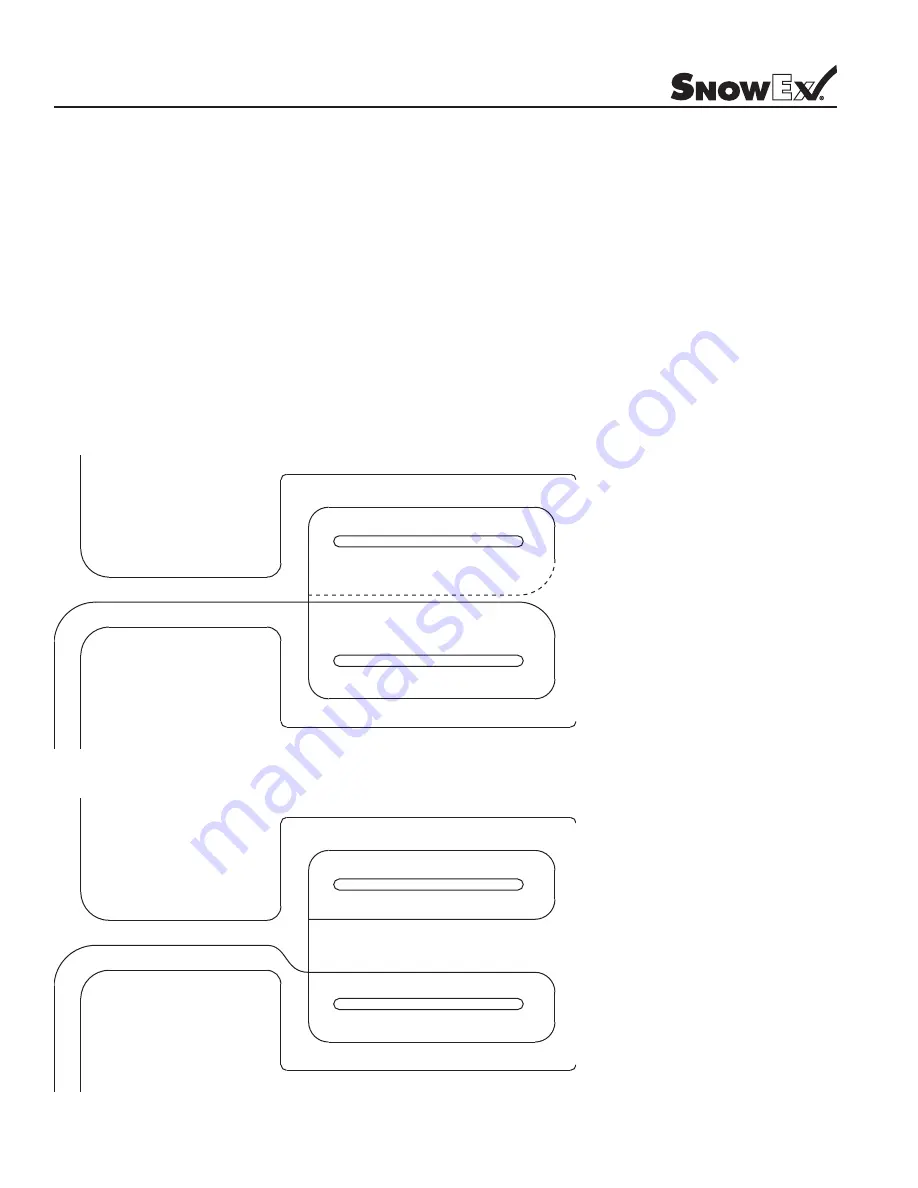

1

5

2 or 4

3

1

Key

1 Constant Speed. Desired application

rate is set.

2 Increase Spinner and Auger speeds to

maintain application rate with a wider

spread pattern.

3 Decrease Spinner and Auger speeds to

maintain application rate with a nar-

rower spread pattern.

4 Increase Spinner Speed and drive

slower.

5 Increase Spread Width and spread

second pass on the way out of the

parking lot.

EXAMPLES:

Содержание SnowEx Precision Pro SP-1675

Страница 11: ...11 TrynEx International 2013 REV A F51073A Notes...

Страница 12: ...133009...