20

Advice on water installation

• You need practical experience to make con-

nections using push-fit systems (e.g. John

Guest or equivalent).

• As regards furnace operation, pressure

pumps and submersible pumps operating

at pressures as high as 40.6 psi (2.8 bar) as

well as hot/cold mixing faucets with or with-

out an electrical switch can be installed.

• If you use a water pump with a pressure

higher than 40 psi (2.8 bar) or if you connect

your system to a city water supply, you must

first install a pressure reducer so that pres-

sure in the water container will not exceed

40 psi (2.8 bar).

• The thermal expansion of water during

heating can result in pressures as high as

65.25 psi (4.5 bar) before the pressure relief/

drain valve responds.

• Water lines connected to the water container

and the drain valve must withstand tempera-

tures in excess of 176 °F (80 °C). They must

also be suitable for potable water and must

withstand pressures as high as 65 psi (4.5 bar).

• If a submersible pump is used, you must in-

stall a non-return valve (Fig. 26 – 6) between

the pump and the first branch.

• If you use pressure pumps that exhibit con-

siderable switching hysteresis, hot water

can flow back via the cold water faucet. You

must install a non-return valve (Fig. 26 – 6)

between the outlet to the cold water faucet

and the pressure relief/drain valve to prevent

backflow. Install the water lines so as to en-

sure that all connected components function

as intended. More specifically, water lines

must be as short, kink-free, and unstressed

as possible.

• Lay cold water lines higher than the pressure

relief/drain valve.

Non-compliance will

void warranty claims for frost damage.

• There must be a clearance of 1 in. (2.5 cm)

between water lines and sources of heat.

• The furnace’s cold water supply must not come

into contact with cold bridges such as the RV’s

side wall on account of the risk of frost.

• An adaptor must be installed at every junc-

tion between a 12 mm push-fit system and

a 1/2 in. CTS tube; see”Installing a 12 mm /

1/2 in. CTS adaptor” on page 20.

•

All hose connections must be secured

by means of clamps or crimp rings, even

cold water.

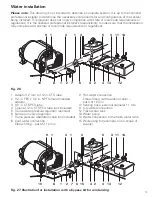

Installing a 12 mm / 1/2 in. CTS

adaptor

An adaptor must be installed at every junction

between a 12 mm push-fit system and a 1/2 in.

CTS tube; see Fig. 28 – 1.

12 mm

Adaptor

1/2 in. CTS tube

2

1

3

1 in. (25 mm)

Fig. 28

1 Adaptor 12 mm to 1/2 in. CTS tube

2 1/2 in. CTS tube

3 Clamp or crimp ring

(not included in scope of delivery)