rollers

RS48-11C ROLL ‘n’ SPIKE GOLF GREENS ROLLER - Operation, Maintenance & Parts Manual

PRE-OPERATION CHECKS

•

Check engine as per Honda / Kohler manual.

•

Ensure steering joystick has no looseness.

•

Check that foot pedal depresses under normal foot pressure, both directions.

•

Ensure that the drawbar locking catch mechanism is securely locked to the main frame bolt & the

safety pin is fitted when trailing the roller.

•

Check and tighten grub screws fitted to the foot pedal arm, the end bearing lock rings on the rubber

coated drive roller and the spiker shaft bearings & pivot bearings on each smoothing head.

•

Grease lightly Bearings fitted to Drive Roller, Spiker shaft & Smoothing Head pivot bearings. Replace

plastic caps if fitted.

•

Oil rod ends, sparingly.

•

Check tire pressure for proper operating pressure (18psi).

•

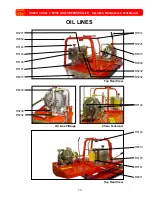

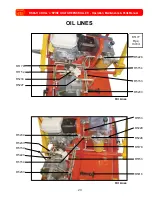

Check for oil and fuel leaks - rectify before using machine.

STANDARD OPERATION PROCEDURES

•

Inspect and check that the roller is serviceable prior to departing from workshop.

•

Use a suitable towing vehicle to move roller from green to green.

•

Maximum recommended towing speed would be equal to a motorized golf buggy. Approximately

4mph/7kph.

Towing at excess speed or across rough terrain may cause damage to the

machine.

•

When approaching the green do not tow roller onto the green to set up, put the roller on the fringe

of the green. Put trailer in the up position, start up the roller and drive it onto the green.

•

Greens can be rolled in any direction; take care to ensure there are no crease lines produced on

the surface.

OPERATION