Greenflame Wood Pellet Boiler 13-18kW

10

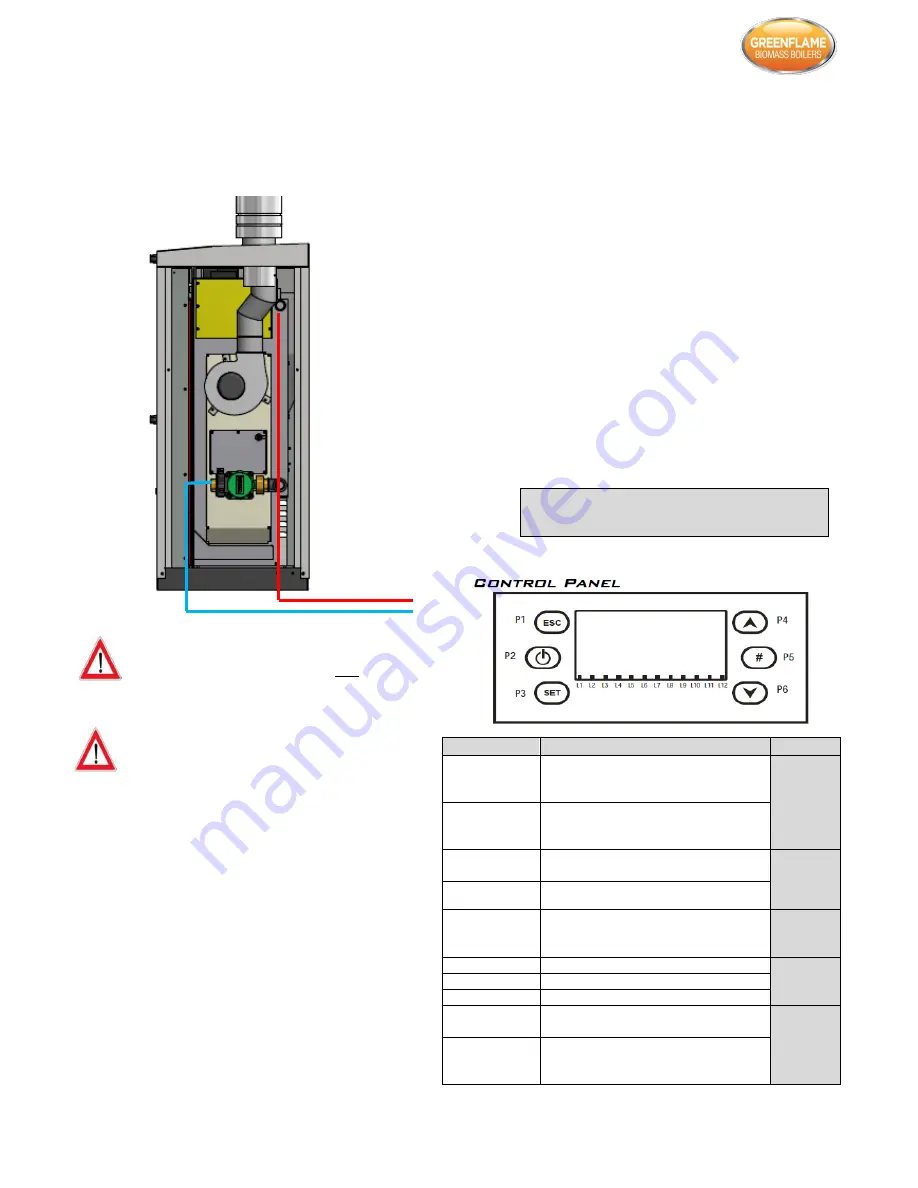

FUNCTION

DESCRIPTION

BUTTON

ON/OFF

Function:

Ignition, Extinguishing

by

pushing the button for 3 seconds until

the acoustic signal.

P2

UNBLOCK

Function:

unblock

. When the system is in

Block by pushing the button for 3

seconds until the acoustic signal.

MODIFY VALUES

INTO MENU

In modify mode change menus and

submenus values.

P4

P6

RUN ON MENU

AND SUBMENU

In Menu run on submenu and menu.

ESC

Function: Exit managed by pushing the

button if in a menu or a submenu. Out of

menu “Pump Test”

P1

MENU

Function: Enter in menu or in a submenu.

P3

MODIFY

Enter in modify mode into a menu.

SET

Save data in a menu.

ENABLE CHRONO

PROGRAMMING

In Chrono menu -> Chrono Program:

enables the selected program.

P5

KEYBOARD LOCK

To lock keyboard keys keep this button

pressed for 3 seconds. To unlock repeat

the same procedure.

4.5 Water Connections

The diagram below indicates the plumbing connections at

the rear of the boiler. The return connection is factory fitted

with a 25/6 standard pump.

Incorrectly sized expansion vessel will invalidate

the warranty. A minimum 18 litre vessel is

recommended for the boiler plus additional

expansion for heating and domestic hot water

system.

Ensure that the pre-charge in the vessel is equal to

the initial system fill pressure of between 1-1.5

bar.

The boiler can be plumbed into either an open vented

system (the maximum static head of water permissible is

90ft. (27.44m) or a sealed system. If plumbed into a sealed

system an appropriately sized expansion vessel should be

used and installed as per manufacturer’s instructions. The

expansion vessel should be sized based on the water

capacity in the boiler and the water in the entire heating

system.

The pump is on the return pipe work just before the boiler. It

is recommended that a by-pass pipe between the flow and

return is used with a valve to regulate the temperature of

the water returning to the boiler. Also, the system designer

should ensure that there is adequate provision in the system

for heat dissipation from the boiler during the shut-down /

extinguishing phase. An automatic air vent and pressure

relief valve must be fitted to the flow pipe work immediately

outside the boiler. The pressure relief valve should be piped

to a drain to prevent injury to the user or service technicians

if it is activated. All unused connections should be sealed

with blanking plugs. A non-return valve should be fitted to

prevent back siphonage.

Once the plumbing has been completed the system should

be fully flushed to clear any debris which may have become

lodged in the pipe work. The system should generally be

filled from the lowest point on the system to force any air to

the highest point where it can be vented. The flow pipe on

the boiler is fitted with a manual air vent for venting air from

the boiler. The system must then be filled and the pump can

be run continuously for a few hours to completely de-aerate

the system. Hold the ESC button on the controller for 3

seconds to activate the pump. Repeat the procedure to turn

it off. Only when the system has been fully vented can the

boiler be commissioned.

The Installation and the design of the central heating system

must be in accordance with BS EN 14336:2004: Heating

systems in buildings. Installation and commissioning of water

based heating systems. BS EN 12828:2003: Heating systems

in buildings. Design of water based heating systems. BS EN

12831:2003: Heating systems in buildings. Method for

calculation of the design heat load.

5. Control System

Always ensure that all connections are making a

watertight seal.