TRI TOOL INC.

92-0699 Rev. 060412

16

6. OPERATION

Read the operating instructions carefully before attempting to operate the Model

204B BEVELMASTER™

Use eye protection at all times when operating the Model 204B BEVELMASTER™

INSTALLATION

Select the recommended jaw blocks for the pipe size to be machined.

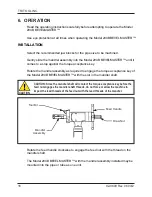

Gently slide the mandrel assembly into the Model 204B BEVELMASTER™ until it

comes to a stop against the torque acceptance key.

Rotate the mandrel assembly as required to engage the torque acceptance key of

the Model 204B BEVELMASTER™ with the slot in the mandrel shaft.

CAUTION

CAUTION: Since the mandrel shaft will contact the torque acceptance key before the

feed nut engages the mandrel shaft threads, do not force or allow the machine to

impact the lead threads of the feed nut with the lead threads of the mandrel.

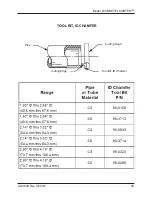

Tool Bit

Mandrel

Assembly

Feed Handle

Draw Nut

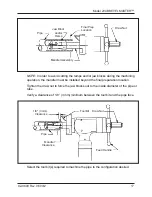

Rotate the feed handle clockwise to engage the feed nut with the thread on the

mandrel shaft.

The Model 204B BEVELMASTER™ with the mandrel assembly installed maybe

mounted into the pipe or tube as one unit.