TRI TOOL INC.

92-0699 Rev. 060412

8

PIPE CUTTING CAPACITIES

Basic Pipe Sizes

All schedules of 1 1/4” through 4” pipe.

Some schedules may require optional equipment.

Basic Tube Size

Up to .531” (13.5mm) wall tubing with a maximum O.D. of 4.50” (114.3mm)

and a minimum I.D. of 1.25” (31.7mm) may be beveled with standard mandrel.

Wall Thickness Capacity

Wall thickness of all standard pipe schedules [.531” (13.5mm) maximum] in the

range listed. Contact Tri Tool for heavier wall procedures.

Counterboring Operations

The tool will counterbore pipe and tubing with an I.D. range of 1.50” (38.1mm)

to 4.33” (110.2mm).

Material Cutting Capabilities

Mild steels, Chrome steels (Rc 35 max), stainless steel, copper-nickel alloys

and aluminum without limitations except size and wall thickness as specified

in paragraph #2.

Inconel and other high temperature alloys may require special procedures

as a function of wall thickness and type of end preparation. Contact Tri Tool’s

Engineering Department for details.

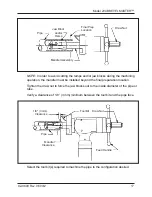

CLEARANCE AND DIMENSIONS

Rotating Head DIA.

4.00” (101.6mm)

Length Over Motor

19.88”

(505.0mm)

Length (of machine)

8.97” (227.8mm)

Available Feed Travel

1.50” (38.1mm)