- 14 -

MAINTENANCE

Your Tri-Clover pump will operate only if the rotors are

correctly installed. Therefore carefully follow the

installation procedure listed below.

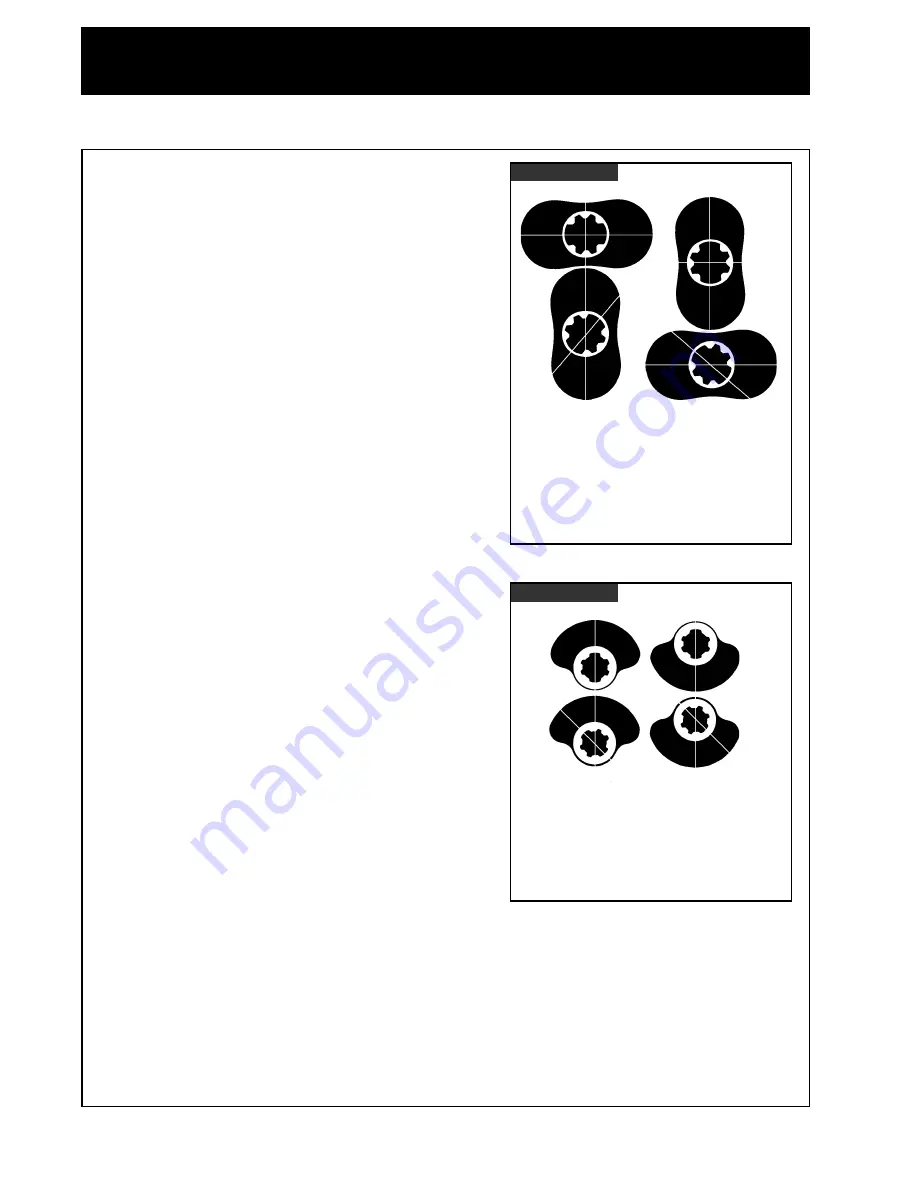

TWO LOBE ROTORS

1.

Install 2D rotor onto top shaft.

Note:

It doesn't matter whether top shaft is pump

shaft or drive shaft.

2.

After installing 2D rotor, rotate shaft if necessary to

obtain spline relationship as shown in Figure 6.

3.

Install 2P rotor on lower shaft. 2P rotor must be

installed as shown in Figure 6. Rotors must form a

"T" shape when properly installed with the tip of

one rotor opposite the concave hub areas of the

mating rotor.

Note:

Pump cannot be operated unless the

above procedure is followed. If rotors are

not installed as shown, the pump will jam

when started resulting in damage to the

rotor or shaft.

SINGLE LOBE ROTORS

1.

Install 1D rotor onto top shaft.

Note:

It doesn't matter whether top shaft is pump

shaft or drive shaft.

2.

After installing 1D rotor, rotate shaft if necessary to

obtain spline relationship as shown in Figure 7.

3.

Install 1P rotor on lower shaft. 1P rotor must be

installed as shown in Figure 7. Large lobe of one

rotor must be next to small diameter or hub of

mating rotor.

Note:

Pump cannot be operated unless the

above procedure is followed. If rotors are

not installed as shown, the pump will jam

when started resulting in damage to the

rotor or shaft.

ROTOR INSTALLATION

Figure Six

Part 2D - Center line of wide spline

teeth is on center line of rotor

lobes.

Part 2P - Center line of wide spline

teeth is at a 45° angle with

center line of rotor lobes.

2D

2D

2P

2P

Figure Six

Part 1D -Center line of wide spline teeth

is on center line of rotor lobes.

Part 1P - Center line of wide spline teeth

is at a 45° angle with center

line of rotor lobes.

1D

1P

1P

1D