29

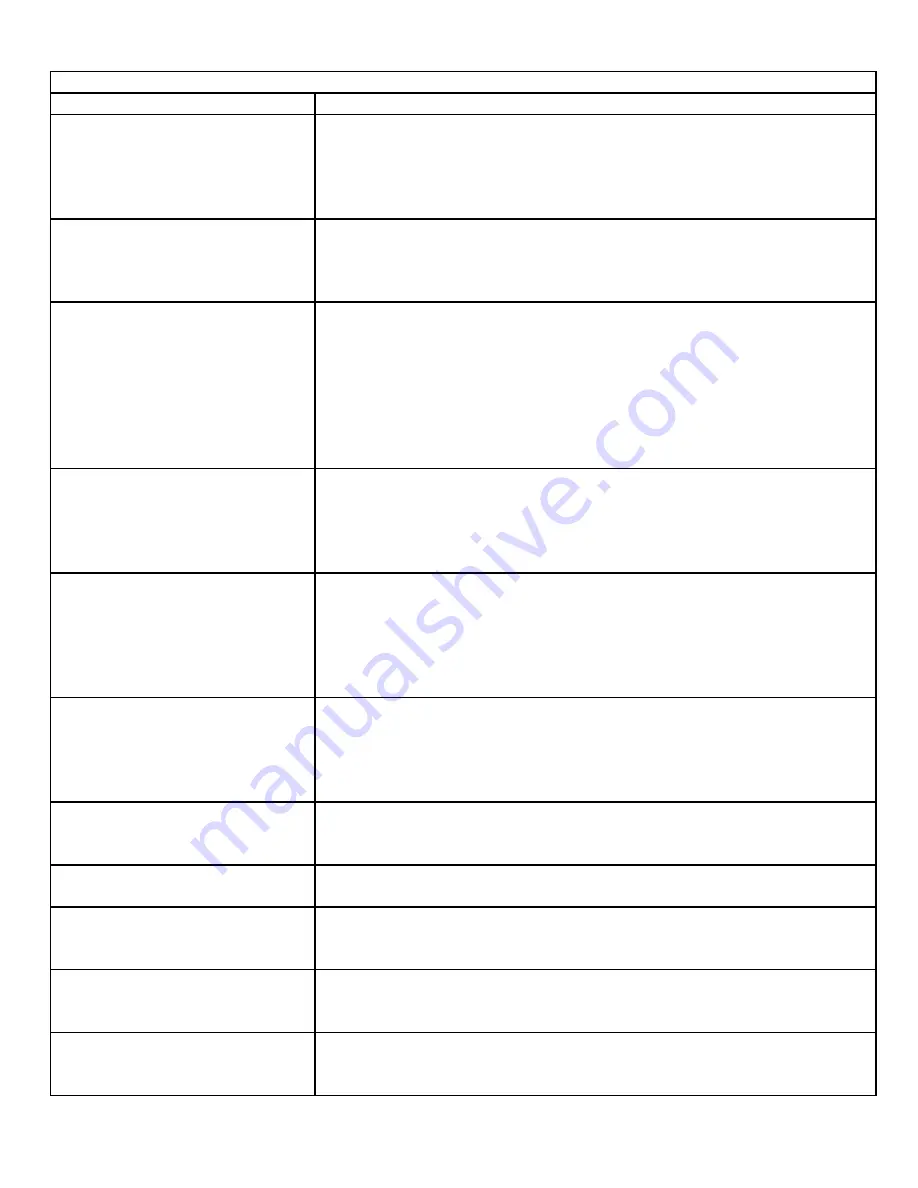

XIII. TROUBLE SHOOTING ( Continued)

CONDITIONS

POSSIBLE SOLUTIONS

LOW SUCTION PRESSURE

1.

Solenoid valve restricted.

2.

Restriction in drier.

3.

Loss of refrigerant.

4.

Poor air flow due to bad blower motor or iced up evaporator coil.

5.

Expansion valve blocked.

HIGH HEAD PRESSURE

1.

Improper airflow across condenser.

2.

Extreme ambient conditions.

3.

Overcharge of refrigerant.

4.

Air in system.

WILL NOT DEFROST

1.

Defrost heater malfunction.

2.

Wired wrong or faulty connection.

3.

Relay contacts open.

4.

Coil temperature sensor failure.

5.

Controller malfunction.

6.

I/O board malfunction.

7.

Power/High voltage board.

8.

Thermal fuse opened

“PRINTER ERROR” ON

1.

Paper not feeding correctly.

DISPLAY

2.

Printer harness.

3.

Printer mechanism/printer board error.

4.

Printer power supply malfunction

5.

Controller malfunction

DISPLAY BLANK

1.

Power supply to controller.

2.

Controller (D21 on)

3.

Main power supply. Should read 5v.

–

12v. & 8.5v

4.

Display harness

5.

Display board malfunction.

6.

Controller malfunction

“ERR”, “SHORT” OR

1.

Probe open.

“OPEN”

2.

Temperature is normally displayed.

3.

Wire connections.

4.

Controller malfunction.

5.

Out of range, actual temperature range (-40°F to 200°F).

PRINTER DOES NOT PRINT

1.

Controller malfunction.

TEST

2.

Printer malfunction.

3.

Printer power supply board malfunction.

PRINTER OUTPUT IS NOT

1.

Controller malfunction.

RECOGNIZABLE.

PRINTER DOES NOT

1.

Printer out of paper (message on display).

PRINT(OPERATOR MODE)

2.

Printer malfunction.

3.

Printer power supply malfunction.

NO RESPONSE FROM

1.

Controller (LED D21on).

KEYPAD

2.

Check keypads.

3.

Check connection to control board.

PRODUCT NOT CHILLED

1.

Product temperature probes not located

2.

Correctly or sensor malfunction.

3.

System malfunction. Refer to SYSTEM TROUBLESHOOTING.

Содержание RBC200RT

Страница 24: ...23 X WIRE DIAGRAM RBC50 2003 2007 https appliancetechmanuals com...

Страница 25: ...24 XI WIRE DIAGRAM RBC100 https appliancetechmanuals com...

Страница 26: ...25 XII WIRE DIAGRAM RBC200 https appliancetechmanuals com...

Страница 33: ...32 XV DATA LOG DIAGNOSTICS https appliancetechmanuals com...