CHAPTER 6: CALIBRATION

6.1 CALIBRATION

OVERVIEW

The indicator is calibrated by following the procedures embedded in F16 (Zero) and F17 (Span) of

the Setup Menu. Each procedure enters a value into the indicator's non-volatile memory - F16 the

zero value (deadweight) and F17 the span value (test weight). The minimum test weight that can be

used is 1% of full-scale capacity. After the two calibration procedures are executed successfully,

you should record both calibration values in Table 6-1 using the F18 View procedure.

In the unlikely event that either value is lost while in the field, the setup menu makes provisions for

re-entering these values via F19 and F20, thus eliminating the need for re-calibration with test

weights.

NOTE:

This chapter assumes that the indicator is in Setup (“F”) Menu mode. If the indicator is not

in Setup Menu mode, refer to Chapter 3 for instructions.

6.2

ZERO CALIBRATION (F16)

1. While in the Setup mode, scroll to "

F 16

", then scroll down once using the UNIT/SET key to

enter zero calibration menu. The display will momentarily show "

C 0

" followed by a value. This

value is the internal A/D count and can prove useful when trying to troubleshoot setup

problems.

2. After making sure that there are no test weights on the platform, press the ZERO key again to

zero out the displayed value.

3. Press the UNIT/SET key to save the zero point value. The display will show "

EndC0

"

momentarily, then revert back up to F16. At this time, proceed to the F17 span calibration to

complete indicator calibration.

6.3

SPAN CALIBRATION (F17)

1. While in the Setup mode, scroll to "

F 17

", then scroll down once using the UNIT/SET key to

enter span calibration menu.

2. The display will momentarily show "

C 1

" for the span calibration, followed by a value with one

flashing digit. This value will be zero with the Decimal Point parameter selected in F10. Place

the test weight on the weighing mechanism.

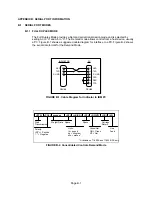

3. Use the directional keys (shown in Figure 6-1 below) to adjust the displayed value to the actual

test weight value. Change the flashing digit by pressing the UNIT/SET key. Pressing the ZERO

key will change the position of the flashing digit.

Neptune 4500 Page 6-1