Since the manufacturer has a policy of continuous product and product

data improvement, it reserves the right to change design and specification

without notice.

Trane

6200 Troup Highway

Tyler, TX 75707

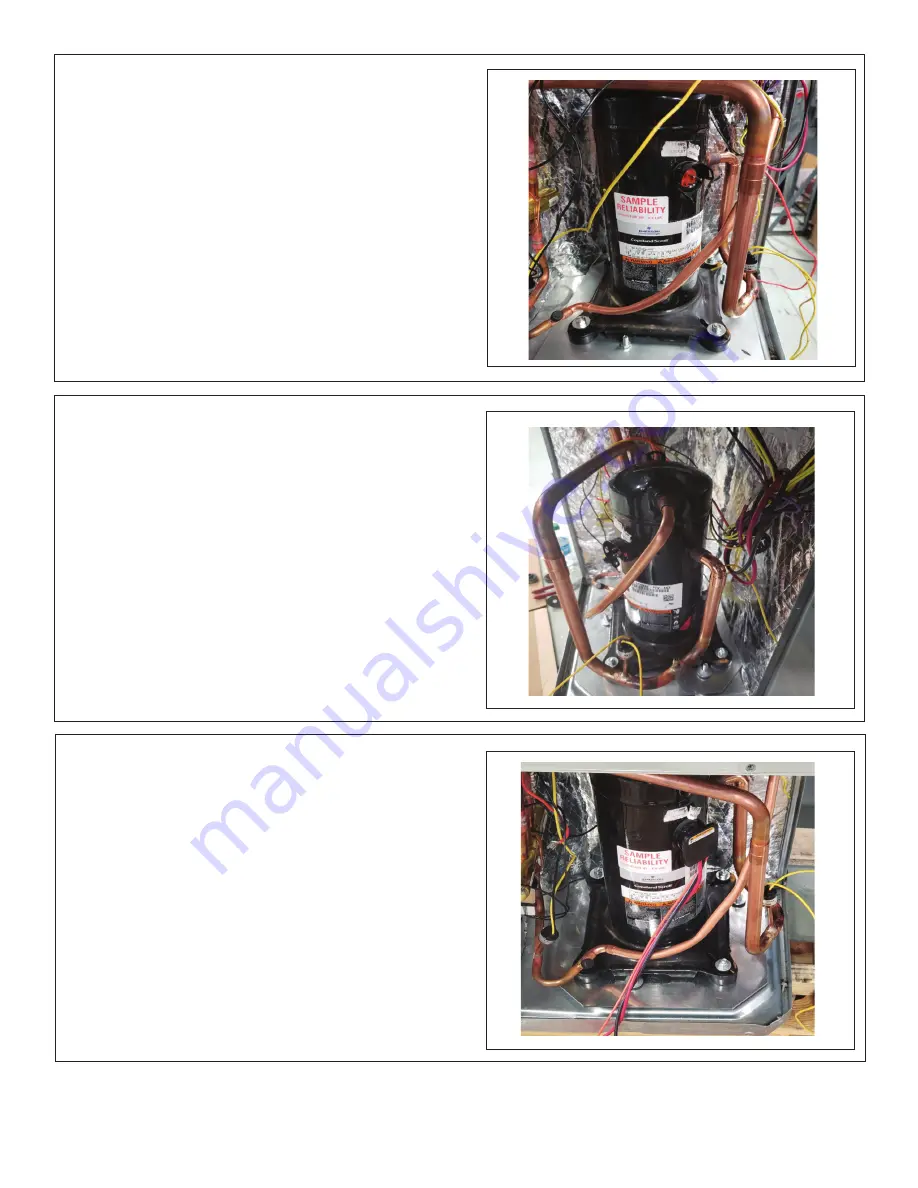

STEP 6

- Braze, leak check with nitrogen, vacuum

and recharge per data plate.

STEP 7

- Install new compressor power lead,

LPCO wires, connect crankcase heater wires and

secure any other wires that were moved during the

compressor replacement. Replace run capacitor if

required in parts notes.

Note

: After and prior to start-up of the new com-

pressor, ensure that all piping and wiring are not in

contact with the access panels when reinstalled.

Note:

If discharge line vibration is an issue, order

part numbers CMP01450 & BAR00178 (clamp and

bar)

Note:

If powered reverse rotation is a problem on

single-phase units, order part number RLY03032

(time delay relay).

STEP 5

- Set the new compressor, tighten the

mounting nuts and use the Trane-supplied

tubing connectors to dry-fit the pipes before

brazing. Replace liquid line drier in the outdoor

coil section of the unit.