Page 2

INSTALLER'S GUIDE

IMPORTANT:

Wear appropriate gloves, arm sleeve protectors,

and eye protection when servicing or maintaining this equipment.

IMPORTANT:

Proper refrigerant charge and proper air flow are

critical to achieve rated capacity and efficiency. Installation of

this product should follow the manufacturer’s refrigerant charging

and air flow instructions.

Failure to confirm proper charge and

airflow may reduce energy efficiency and shorten equipment

life.

IMPORTANT:

Reconnect all grounding devices. All parts of this

product capable of conducting electrical current are grounded. If

grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position and properly fastened.

CAUTION

!

CAUTION

!

CONTAINS REFRIGERANT!

SYSTEM CONTAINS OIL AND REFRIGERANT UNDER

HIGH PRESSURE. RECOVER REFRIGERANT TO RELIEVE

PRESSURE BEFORE OPENING SYSTEM. Failure to follow

proper procedures can result in personal illness or injury

or severe equipment damage.

CAUTION

!

RECONNECT ALL GROUNDING DEVICES.

All parts of this product that are capable of conduct-

ing electrical current are grounded. If grounding wires,

screws, straps, clips, nuts, or washers used to complete

a path to ground are removed for service, they must be

returned to their original position and properly fastened.

CAUTION

!

Hot Surface!

Do Not touch top of compressor. May cause minor to severe

burning.

Unit contains R-410A Refrigerant!

R-410A operating pressure exceeds the limit of R-22. Proper

service equipment is required. Failure to use proper service

tools may result in equipment damage or personal injury.

SERVICE

Use only R-410A Refrigerant and approved POE com-

pressor oil.

These units use R-410A refrigerant which operates at

50 to 70% higher pressures than R-22. Use only R-410A

approved service equipment. Refrigerant cylinders are

painted a “Rose” color to indicate the type of refriger-

ant and may contain a “dip” tube to allow for charging

of liquid refrigerant into the system. All R-410A sys-

tems use a POE oil that readily absorbs moisture from

the atmosphere. To limit this “hygroscopic” action, the

system should remain sealed whenever possible. If a

system has been open to the atmosphere for more than

4 hours, the compressor oil must be replaced. Never

break a vacuum with air and always change the driers

when opening the system for component replacement.

For specific handling concerns with R-410A and POE oil

reference Retrofit Bulletins SS-APG006-EN and APP-

APG011-EN.

s

WARNING

Important:

Make sure to follow all safety precautions in the

unit Installer's Guide.

Important: Make certain that the unit has been installed in

a level position to ensure proper draining.

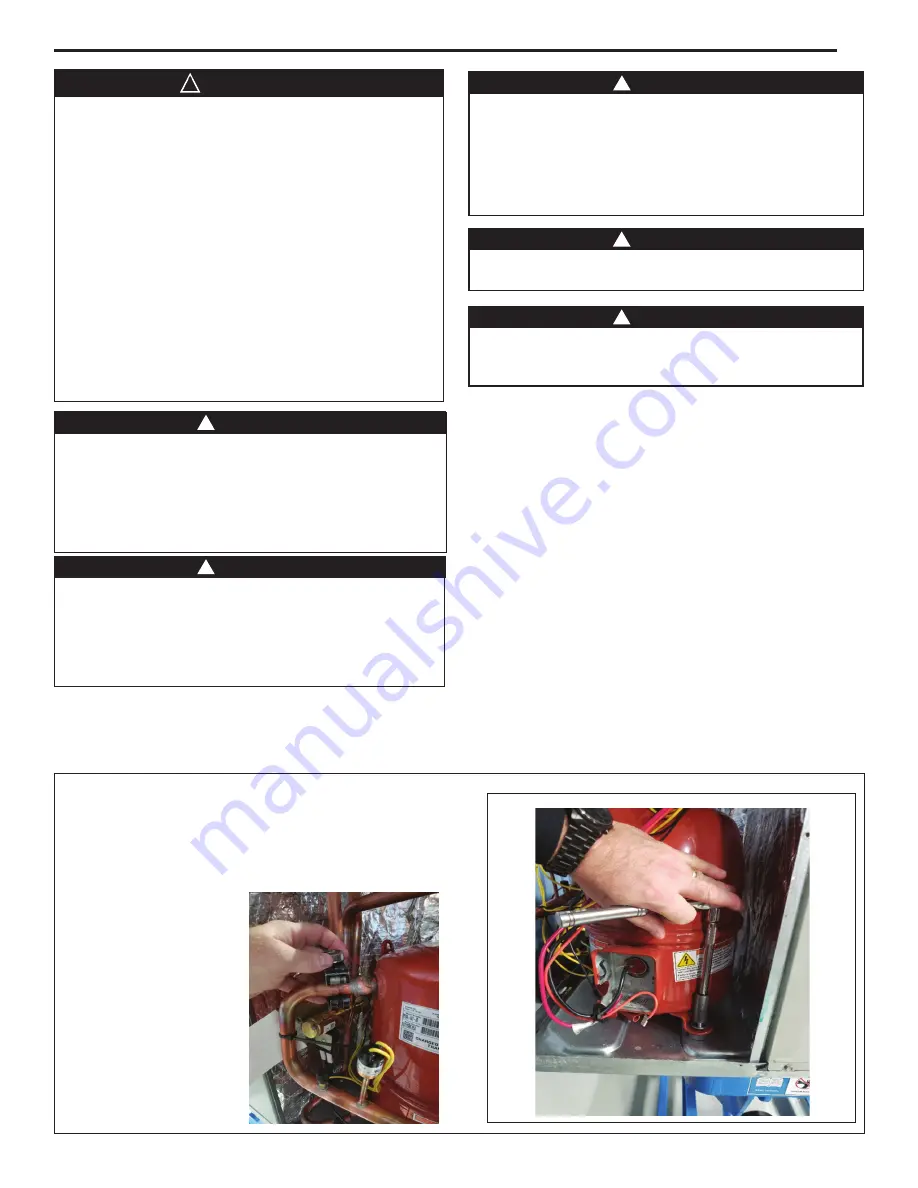

STEP 1

- Recover refrigerant, disconnect power leads

and remove mounting washers/nuts and set aside

from the existing compressor. Also disconnect LPCO

wires from the wire termination point. If a start kit is

installed, remove it.

Section 2. Installation

CAUTION

!

If using existing refrigerant lines make certain that all joints

are brazed, not soldered.