CVGF-SVU02B-E4

80

Weigh the cylinder as the oil is

being transferred and shut off

the cylinder valve when the

desired weight of oil has been

transferred. Backseat the angle

valve to shut off oil flow and

remove the hose from the

Schrader valve. Be sure to

replace the Schrader and angle

valve cap and secure them when

sampling is complete. Recover

the oil and refrigerant from the

oil sample hose or line with an

approved R134a recovery unit.

When oil analysis indicates the

need to change the oil (high

acidity, moisture, and so forth),

use the following procedure for

removing the oil.

Removing Compressor Oil

Make sure the unit is not running

and the power has been

disconnected to the oil heaters.

To remove the compressor oil,

attach an oil recovery and

recharge hose or line to the oil

sump drain valve located on the

bottom of the oil sump (See

Figure 24. Attach the refrigerant

vapor return hose or line of the

recovery unit to the condenser

service valve. Open the oil sump

drain valve and condenser

service valve and activate the oil

recovery process according to

the operation specifications of

the recovery unit. After all the oil

has been recovered and residual

R134a refrigerant vapor returned

to the condenser, shut the oil

drain valve and condenser

service valve off and secure the

caps to both valves.

Periodic

Maintenance

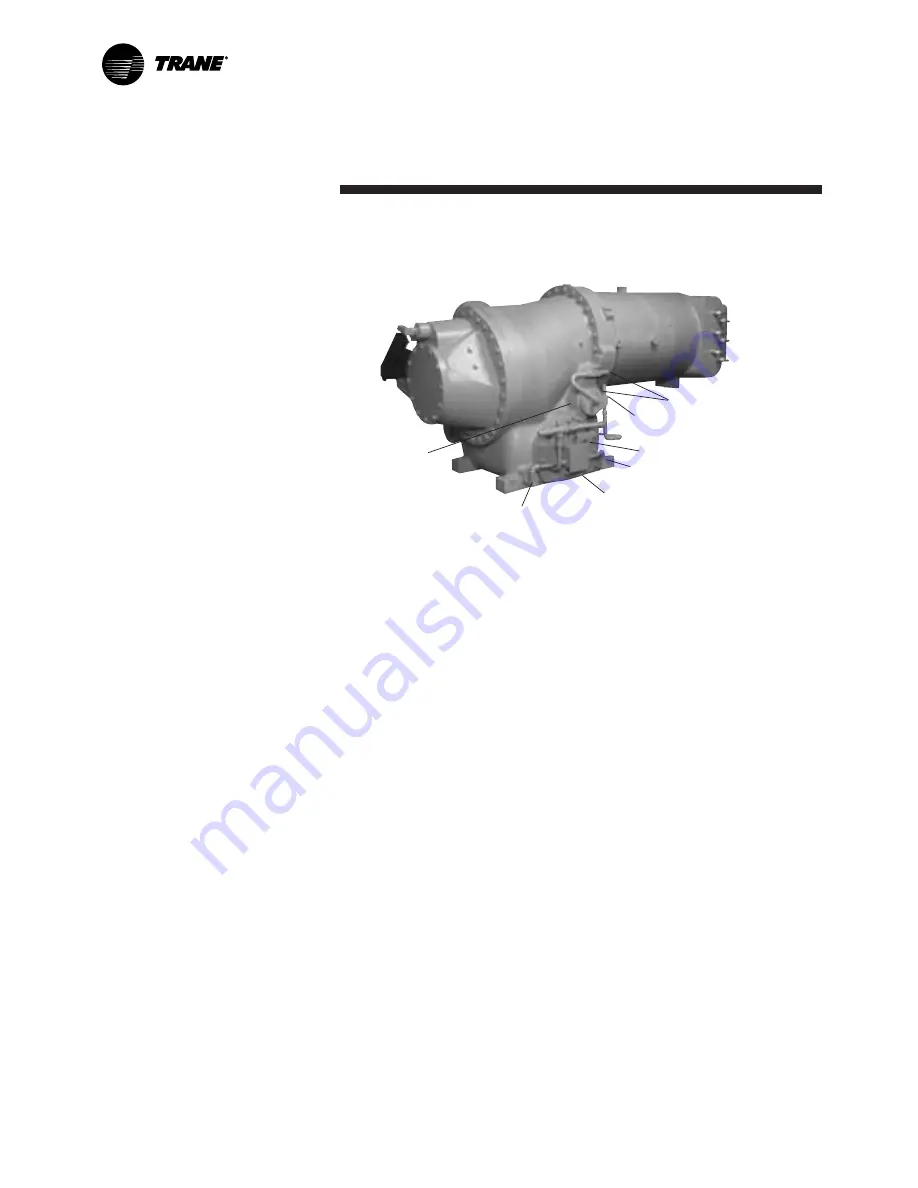

Figure 24. CVGF compressor oil system component locations

Oil filter isolation valves

1/4” Schrader valve

Oil level sightglasses

Oil heater - 500 w

Oil sump drain valve

Oil Heater - 500 w

Oil filter cover

Содержание CVGF 1000

Страница 87: ......