UHM-DHM-SF-1H

29

Service Facts

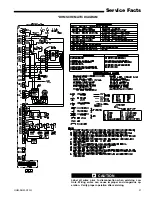

*DHM AIRFLOW - HEATING

0.1

0.3

0.5

0.7

0.9

CFM

666

657

643

628

609

Temp. Rise

59

59

61

62

64

Watts

24

92

116

206

206

CFM

710

701

686

670

650

Temp. Rise

55

56

57

58

60

Watts

32

105

128

220

227

CFM

732

723

708

690

670

Temp. Rise

53

54

55

56

58

Watts

36

111

134

227

237

CFM

755

744

729

711

690

Temp. Rise

52

52

53

55

56

Watts

40

118

140

235

247

CFM

1077

1063

1041

1016

985

Temp. Rise

59

59

61

62

64

Watts

128

237

237

368

398

CFM

1149

1134

1110

1083

1051

Temp. Rise

55

56

57

58

60

Watts

153

270

262

404

432

CFM

1185

1169

1145

1117

1084

Temp. Rise

53

54

55

56

58

Watts

166

286

275

422

449

CFM

1221

1205

1180

1151

1117

Temp. Rise

52

52

53

55

56

Watts

180

304

288

441

466

CFM

1496

1476

1446

1410

1368

Temp. Rise

59

59

61

62

64

Watts

304

455

396

604

596

CFM

1596

1575

1542

1504

1460

Temp. Rise

55

56

57

58

60

Watts

356

517

438

670

643

CFM

1646

1624

1590

1551

1505

Temp. Rise

53

54

55

56

58

Watts

384

550

461

705

667

CFM

1696

1673

1639

1598

1551

Temp. Rise

52

52

53

55

56

Watts

413

583

483

726

726

Medium**

1650

High

1700

1500

Medium Low

1600

High

1224

Heat

in

g

*DHMC100ACV4VA^

Furnace Heating Airflow (CFM) and Power (Watts) vs. External Static Pressure With Filter

Airflow

Setting

100%

(high)

Heat

Low

65%

(medium)

Heat

Low

1080

Medium Low

1188

Medium**

734

High

757

Target Airflow

(See Note 5)

External Static Pressure

40% (low)

Heat

Low

668

Medium Low

712

1152

Medium**

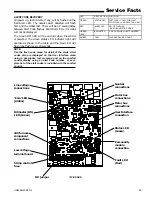

0.1

0.3

0.5

0.7

0.9

CFM

827

870

800

779

785

Temp. Rise

57

55

59

61

60

Watts

76

98

142

175

212

CFM

871

917

846

827

834

Temp. Rise

55

52

56

57

57

Watts

85

108

153

188

226

CFM

911

959

889

872

878

Temp. Rise

52

50

53

54

54

Watts

94

117

165

201

240

CFM

994

1047

977

964

969

Temp. Rise

48

45

49

49

49

Watts

116

140

191

230

272

CFM

1214

1282

1211

1209

1212

Temp. Rise

57

54

57

57

57

Watts

193

223

285

334

385

CFM

1281

1353

1282

1283

1286

Temp. Rise

54

51

54

53

53

Watts

224

255

322

375

431

CFM

1470

1553

1482

1493

1493

Temp. Rise

47

44

46

46

46

Watts

329

366

449

517

592

CFM

1671

1767

1696

1717

1715

Temp. Rise

41

39

40

40

40

Watts

479

519

633

722

831

CFM

1648

1743

1671

1691

1690

Temp. Rise

64

61

63

62

62

Watts

459

499

609

695

799

CFM

1741

1842

1770

1795

1792

Temp. Rise

61

57

60

59

59

Watts

541

582

709

808

932

CFM

1825

1931

1859

1888

1885

Temp. Rise

58

55

57

56

56

Watts

624

663

811

922

1068

CFM

2002

1983

1977

1902

1853

Temp. Rise

53

53

53

55

57

Watts

827

925

925

925

925

External Static Pressure

780

827

870

Target Airflow

(See Note 5)

1850

959

1195

1267

1469

Low

1685

1660

1760

100% (high) Heat

2040

Low

Medium Low

Medium**

High

Low

Medium Low

Medium**

High

Airflow Setting

*DHMD120BCV5VA^

Furnace Heating Airflow (CFM) and Power (Watts) vs. External Static Pressure With Filter

Medium Low

Medium**

High

40% (low) Heat

65% (medium)

Heat

H

eating

Notes:

1. * First letter may be "A" or "T".

3. ** Factory setting.

2. ^ Letter may be “A” through “Z”.

4. Continuous Fan Setting: Heating or cooling airflow is approximately 50% of selected

cooling value.

5. LOW 350 cfm/ton is recommended for variable speed application for COMFORT & HUMID

CLIMATE setting; NORMAL is 400 cfm/ton; HIGH 450 cfm/ton is for DRY CLIMATE setting.

6. Target airflow is field selectable for high (100%) heat. Target airflow for low and medium

heat are percentages of high heat and are not field selectable.

Содержание ADHMB060BCV3VA

Страница 37: ...UHM DHM SF 1H 37 Service Facts...

Страница 39: ...UHM DHM SF 1H 39 Service Facts...

Страница 41: ...UHM DHM SF 1H 41 Service Facts...

Страница 47: ...UHM DHM SF 1H 47 Service Facts...

Страница 49: ...UHM DHM SF 1H 49 Service Facts...

Страница 51: ...UHM DHM SF 1H 51 Service Facts...

Страница 53: ...UHM DHM SF 1H 53 Service Facts NOTES...