18-AD41D1-1B-EN

3

Installer’s Guide

Maximum airflow setting, CFM

Coil

Upflow Downflow

Horizontal

Left

Horizontal

Right

4PXC*U24BS3HAB

900

750

800

900

4PXC*U30BS3HAB 1125

925

1000

1125

4PXC*D30BS3HDB

n/a

n/a

4PXC*U32BS3HAB

1350

1200

1350

1350

4PXC*U36BS3HAB

1100

1200

4PXC*D36BS3HDB

n/a

n/a

4PXC*U42BS3HAB 1575

1300

1400

1575

4PXC*D42BS3HDB

n/a

n/a

4PXC*U48BS3HAB 1800

1475

1600

1800

4PXC*U60BS3HAB 2250

1850

2000

2250

4PXC*D60BS3HDB

n/a

n/a

* May be "A", "B", "C", or "D"

F. MAXIMUM AIRFLOW SETTING, CFM

NOTE:

Water blow-off could occur in certain installation posi-

tions if the airflow setting exceeds the maximum values

listed.

IMPORTANT:

Do not unseal refrigerant tubing until ready to fit refrigerant

lines.

There is only a holding charge of dry air in the indoor coil, therefore

no loss of operating refrigerant charge occurs when the sealing

plugs are removed.

G. INSTALLING / BRAZING REFRIGERANT LINES

Do NOT open refrigerant valve at the outdoor unit until the

refrigerant lines and coil have been brazed, evacuated, and

leak checked. This would cause contamination of the refrig-

erant or possible discharge of refrigerant to the atmosphere.

1. The following steps are to be considered when installing

the refrigerant lines:

a. Determine the most practical way to run the lines.

b. Consider types of bends to be made and space

limitations.

c. Route the tubing making all required bends and

properly secure the tubing before making final

connections.

NOTE:

Refrigerant lines must be isolated from the structure and

the holes must be sealed weather tight after installation.

NOTE:

The TXV setting on this unit may run high superheat

(15-25°F) by design when measured at the outdoor unit.

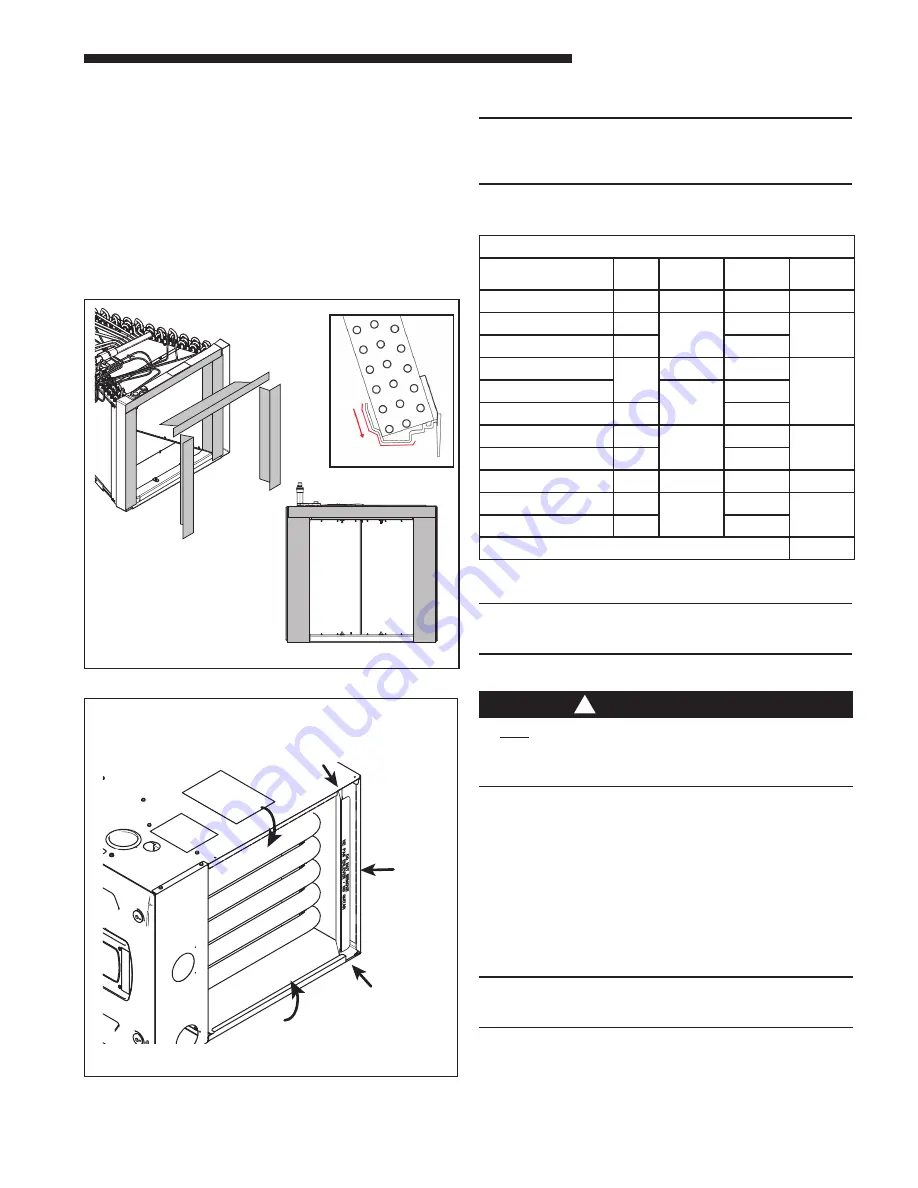

Figure 4

Attach Downflow

Bottom Gasket

Start

here

Figure 5

Note: when installing coil onto an S-Series furnaces

in horizontal right or downflow configuration, bend

the flanges downward for a flush fit.

a. Lay the coil on its back side.

b. Locate the 4" wide gasket material found in

BAYGSKT001A0.

c. Attach the 4" gasket material to three sides of the bottom

of the drain pan as shown. Make sure to start by matching

up the edge of the gasket material to the inner edge of the

drain pan by the coil fins and working outwards.

d. The gasket material can be cut or ripped easily so that it

can be tailored to fit. The gasket material must cover

the three sides along the entire length of the coil as shown

in Figure 4.

CAUTION

!