2

18-AD41D1-1B-EN

Installer’s Guide

CAUTION

!

Caution: This coil is pressurized with 8-12 psig of dry

air. Do not stand directly in front of the coil connections

when removing sealing plugs. If no pressure is released,

check for leaks.

C. RECOMMENDATION

If a coil is part of the total system installation, use the Installer’s

Guide packaged with the furnaces, outdoor sections, and ther-

mostat for physically installing those components.

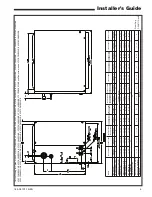

UPFLO

W

FURNA

CE

CASED

COIL

SCREWS

(BOTH SIDES)

SELF TAPPING SCREWS (4)

1-1/2” MAXIMUM

FIELD SUPPLIED

FOR UPFLOW /

HORIZONTAL LEFT

INSTALLATIONS

E. FURNACE IN DOWNFLOW POSITION

1. UPFLOW COIL CONVERSION (Models:

4PXCBU36BS3HAB, 4PXCCU36BS3HAB,

4PXCBU42BS3HAB, 4PXCCU42BS3HAB,

4PXCBU48BS3HAB, 4PXCCU48BS3HAB,

4PXCDU48BS3HAB, 4PXCCU60BS3HAB,

4PXCDU60BS3HAB only)

a. For maximum efficiency, remove the factory installed

two-piece baffle assembly from the apex of the coil by

removing the 5/16” hex head screws. See Figure 2.

b. Replace only the top baffle using the same screws

previously removed.

1. DOWNFLOW GAS FURNACE

When a coil is used with a downflow furnace, a subbase

is not required between the coil case and combustible

flooring.

a. Place the coil case on the furnace supply air plenum.

b. Secure the coil case to the plenum.

c. Set the furnace on top of the coil case, making sure

that the back side of the discharge opening is snug up

against the duct flange at the top rear of the coil case.

d. Secure the coil case to the furnace and seal for air

leaks as required.

CAUTION

!

Caution: This coil is pressurized with 8-12 psig of dry

air. Do not stand directly in front of the coil connections

when removing sealing plugs. If no pressure is released,

check for leaks.

D. FURNACE IN UPFLOW POSITION

APPLICATION USES UPFLOW COIL MODELS ONLY

IMPORTANT:

If installing the coil in the horizontal position, you MUST

use the horizontal kit listed below for this coil model num

-

ber and follow the instructions in the installation guide

provided with the conversion kit.

Model Number

Horizontal Kit No.

4PXCAU24BS3HAB

4PXCAU32BS3HAB

4PXCBU24BS3HAB

4PXCBU30BS3HAB

4PXCCU30BS3HAB

4PXCBD30BS3HDB

BAYCONV18B

4PXCBU36BS3HAB

4PXCCU36BS3HAB

4PXCBD36BS3HDB

4PXCCD36BS3HDB

BAYCONV23B

4PXCBU42BS3HAB

4PXCCU42BS3HAB

4PXCBU48BS3HAB

4PXCCU48BS3HAB

4PXCDU48BS3HAB

4PXCBD42BS3HDB

4PXCCD42BS3HDB

BAYCONV27B

4PXCCU60BS3HAB

4PXCDU60BS3HAB

4PXCCD60BS3HDB

4PXCDD60BS3HDB

BAYCONV30B

Figure 3

Figure 2

Remove

and

Discard

Replace

NOTE:

4PXC upflow coils may be installed in Upflow, Downflow,

Horizontal Right with kit, and Horizontal Left with kit.

4PXC downflow coils may be installed in Downflow and

Horizontal Right with kit.

2. UPFLOW GAS FURNACE

a. Apply gasket material (duct seal field supplied) to ALL

mating surfaces between the furnace and the coil case.

b. Set the coil case on top of the furnace. Connect the

ductwork to the coil case using field supplied screws.

See Figure 3.

c. Secure the coil case to the furnace and seal for air

leaks as required.

2. DOWNFLOW GASKET INSTALLATION (OPTIONAL):

For unusually humid applications that expect prolonged

operation above 70% RH, it is recommended to use the

BAYGSKT001A0 gasket kit to prevent water from forming

on the bottom of the drain pan and dripping into the supply

ductwork.