24

Southwestern Industries, Inc.

TRAK

KMX Knee Mill, Bed Mill & ProtoTRAK

KMX CNC Retrofit Safety, Programming, Operating & Care Manual

4.2.2

Table, Saddle, Knee and Column Gib Locks

The table clamps are located on the front of the saddle. Rotate them clockwise

until snug--overtightening is not necessary.

The saddle clamp is located on the left side of the saddle. Rotate clockwise to

clamp the table until snug--overtightening is not necessary.

The knee clamps are located on the left side of the knee.

CAUTION!

Do not run ProtoTRAK KMX program unless the table and saddle clamps are free.

4.2.3

Raising/Lowering the Knee

The knee is raised and lowered using the hand crank located on the left front of

the knee. Clockwise rotation moves the knee up, while counterclockwise rotation

moves the knee down.

Be sure the knee is unclamped before raising or lowering.

4.2.4

Spindle Brake

The mechanical spindle break is activated pulling it down, or pushing it up.

When the lever arm is in the horizontal position, the brake is off.

CAUTION!

Be certain that the spindle brake is released before starting the motor. Never

attempt to activate the spindle brake when the motor is on.

4.2.5

Draw Bar

The draw bar holds the R8 tool holders into the spindle taper. The bar has a

7/16-20 right hand thread and should be tightened with a 23mm wrench from

the top of the head. When tightening, it is necessary to activate the spindle

brake (See 4.2.4 above). If the tool holder does not release from the spindle,

lightly tap on the top of the bar to dislodge the tool.

4.2.6

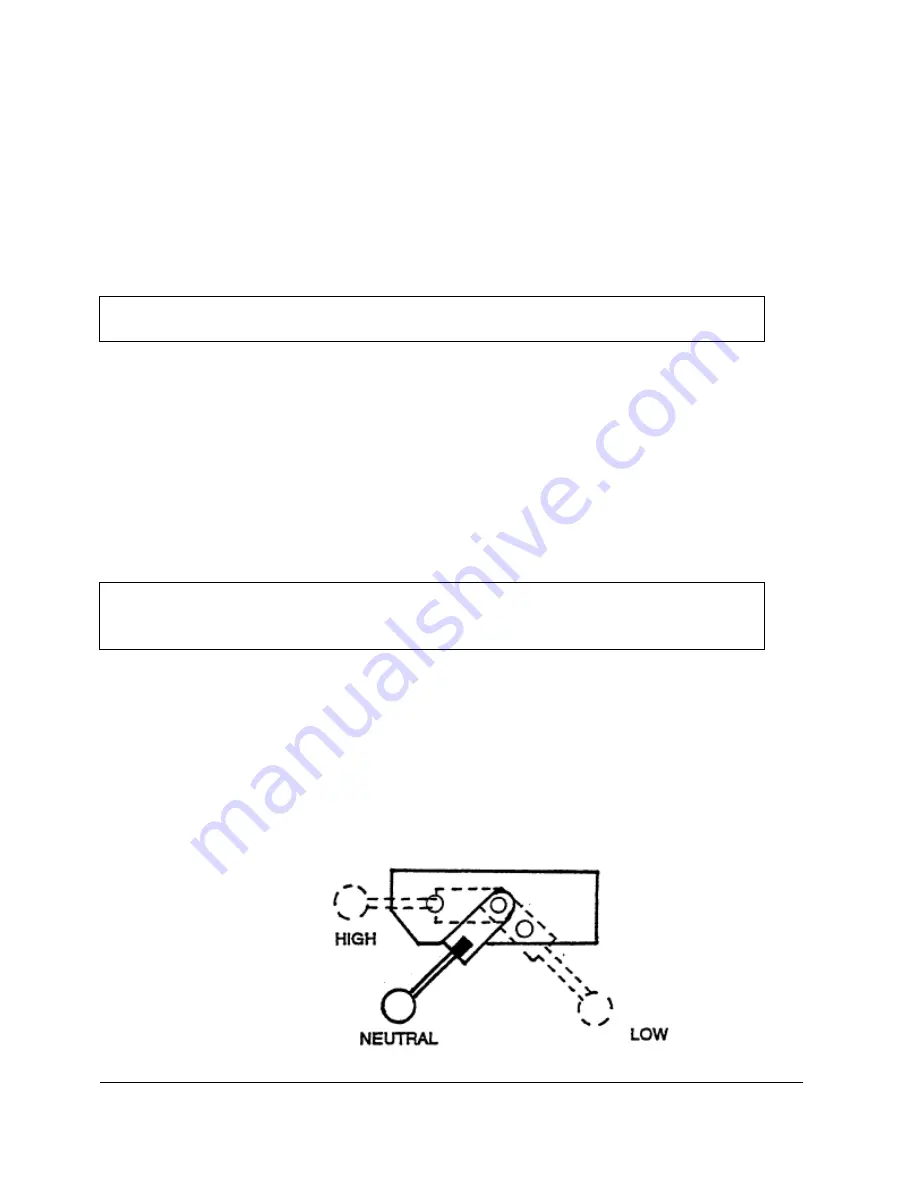

High-Low-Neutral Level

The spindle RPM range selection is made through the High-Low-Neutral Lever.

Figure 4.2.6