Assembly Instructions | ILM Servo Kits

25

Edition 03/2021 EN

Assembly

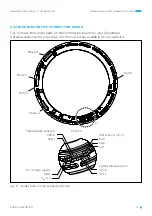

7.3.3 Double rotor

A double rotor is needed for some versions of the ILM servo kits, for example some with

Hall commutation. For this purpose, the rotor length is extended so that the rotation

can be detected by the Hall sensors on the connection board. Installation of the double

rotor is described in a separate document which is available on our website.

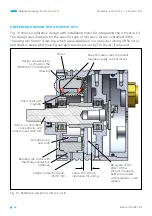

7.4 Inserting the rotor into the stator

WARNING

Danger of crushing, catching or cutting injuries to the hands.

For example, the rotor can move suddenly under the effect of magnetic forces. This can

result in severe injuries.

►

To prevent sudden movements of the rotor during installation, use a mechanical means

to lock the rotor in place.

►

When inserting the rotor into the stator, use a mechanical centring guide to prevent

the rotor moving suddenly towards the stator due to magnetic attraction.

►

Wear safety goggles to protect your eyes and wear safety gloves until you have fin-

ished installing the ILM servo kit.

NOTE

►

Make sure that the rotor is not tilted as it is inserted, otherwise parts of the magnets

on the rotor can splinter off or the inner surface of the stator and other parts can be

damaged.

►

When inserting the rotor into the stator, be aware of the powerful magnetic forces that

can pull the rotor suddenly into the stator. The centring aid must therefore be held in

place with appropriate force.

►

Use a mechanical centring guide to insert the rotor into the stator.