ST03U--01

P00301

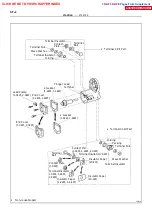

Ohmmeter

Continuity

P00302

Ohmmeter

No Continuity

P00228

P00229

ST0040

--

STARTING

STARTER

ST--5

INSPECTION

1. INSPECT COMMUTATOR FOR OPEN CIRCUI T

Using an ohmmeter, check that there is no continuity between

the commutator and armature coil core.

If there is continuity, replace the armature.

2. INSPECT COMMUTATOR FOR GROUND

Using an ohmmeter, check that there is no continuity between

the commutator and armature coil core.

If there is continuity, replace the armature.

3. INSPECT COMMUTATOR FOR DIRTY AND BURNT

S URFACE S

If the surface is dirty or burnt, correct it with sandpaper (No. 400)

or on a lathe.

4. INSPECT COMMUTATOR CIRCLE RUNO UT

(a)

Place the commutator on V--blocks.

(b)

Using a dial indicator, measure the circle runout.

Maximum circle runout: 0.05 mm (0.0020 in.)

If the circle runout is greater than the maximum, correct it on a

lathe.

5. INSPECT COMMUTATOR DIAMETER

Using vernier calipers, measure the commutator diameter.

Standard diameter:

1.0kW, 1.2 kW, 1.4kW type:

30 mm (1.18 in.)

2.0 kW type:

35 mm (1.378 in.)

Minimum diameter:

1.0kW, 1.2 kW, 1.4kW type:

29 mm (1.14 in.)

2.0 kW type:

34 mm (1.339 in.)

If the diameter is less than the minimum, replace the armature.

6. INSPECT UNDE RCUT DE P T H

Check that the undercut depth is clean and free of foreign mate-

rials. Smooth out the edge.

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE