5

6

Remember: Take your time and follow directions to end up with

a well-built model that is straight and true.

Please inspect all parts carefully before starting to build! If any

parts are missing, broken or defective, please call us at

(800) 637-6050 (Outside the USA - (217) 398-3636) and we’ll

be glad to help. Or, you may send an e-mail to:

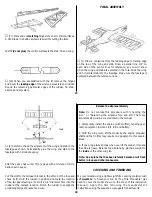

IMPORTANT BUILDING NOTES

Unroll the plan sheets, then reroll the plans inside-out to make

them lie flat.

Sort through the sticks and sheets, grouping them by size.

Masking tape can be used to bundle matching sheets and sticks.

Using a felt tip or ball point pen, lightly write the part name or

size on each piece or bundle. Refer to the parts list and plans for

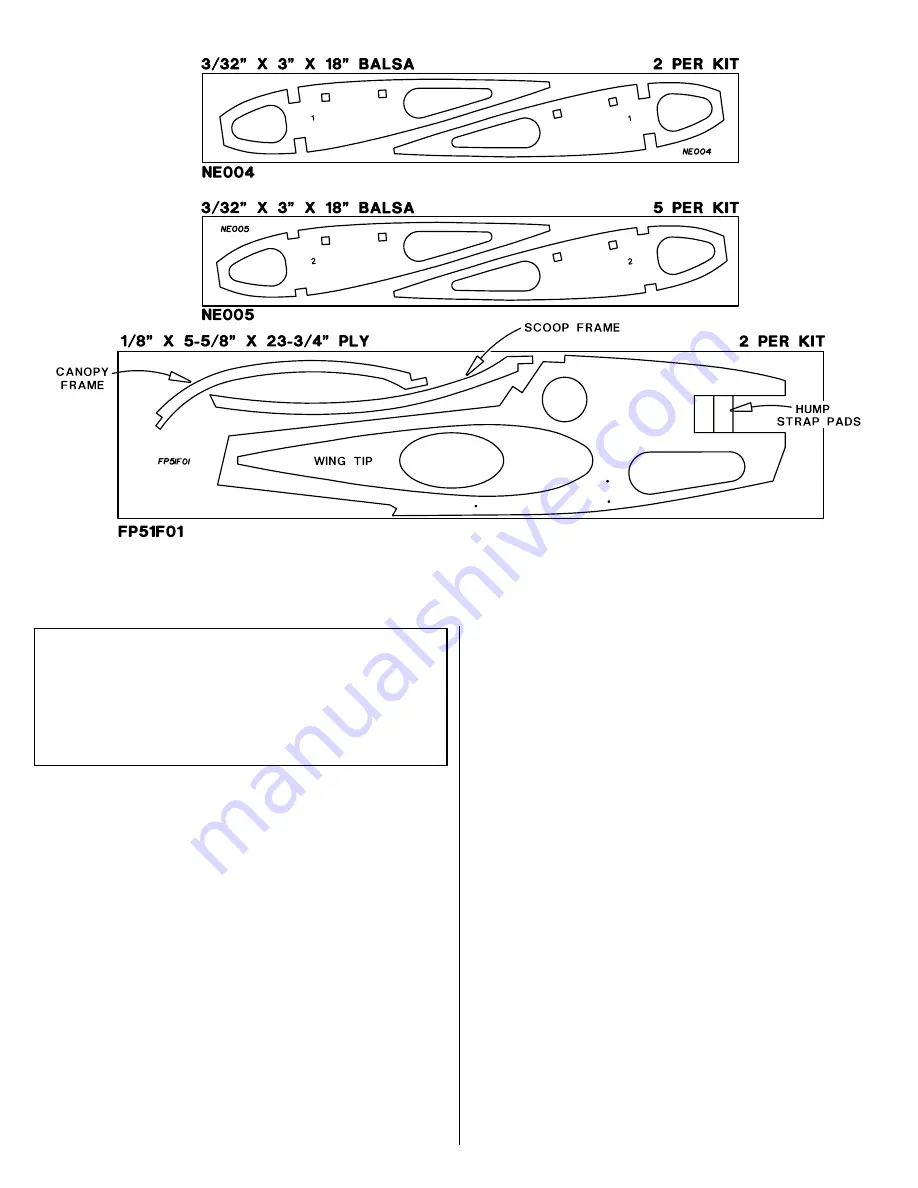

sizes and quantities. Use the die-cut patterns shown on page 5

to identify the die-cut parts and mark them before removing

them from the sheet. Save all scraps. If any of the die-cut parts

are difficult to remove, do not force them! Instead, cut around

the parts with a hobby knife or lightly sand the back of the sheet.

After removing the die-cut parts, use your sanding block to

lightly sand the edges to remove any die-cutting irregularities.

Work on a flat surface. Cover the plans with wax paper or Great

Planes Plan Protectors (GPMR6167). There are notes on the

plans that tell you what material to use to make each part.

When instructed to

test fit parts, this means DO NOT USE GLUE

until you are satisfied that everything fits properly – THEN glue

the parts together when instructed to do so.

The easiest way to cut balsa sticks is with a single edge razor blade

or razor saw. Position the stick over the plan, mark its size and then

cut the part on a piece of scrap lumber. A modeling miter box

works well for cutting square corners and 45 degree gussets.

We, as the kit manufacturer, provide you with a top quality kit

and great instructions, but ultimately the quality and flyability

of your finished model depends on how you build it;

therefore, we cannot in any way guarantee the performance of

your completed model, and no representations are expressed

or implied as to the performance or safety of your completed

model.

DIE PATTERNS