– 37 –

CAUTION

Installation in the following places may result in

trouble. Do not install the unit in such places.

• A place full of machine oil.

• A saline place such as coast.

• A place full of sulfide gas.

• A place where high-frequency waves are likely

to be generated as from radio equipment,

welders, and medical equipment.

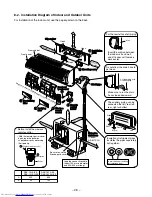

8-5-1. Required Tools for Installation Work

1) Philips screw driver

2) Hole core drill (65mm)

3) Gaugramanifold

4) Spanner

5) Pipe cutter

6) Knife

7) Reamer

8) Gas leak detector

9) Tape measure

10) Thermometer

11) Mega-tester

12) Electro circuit tester

13) Vacuum pump

14) Hexagonal wrench (5mm)

15) Torque wrench

8-5-2. Refrigerant Piping Connection

<Flaring>

(1) Cut the pipe with a pipe cutter.

90˚

Obliquity

Roughness

Warp

Half union or packed valve

Flare nut

Externally

threaded

side

Internally

threaded

side

Use a wrench

to secure.

Use a torque wrench

to tighten.

Fig. 8-5-4

Fig. 8-5-2

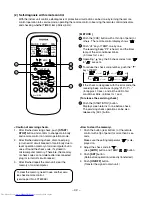

(2) Insert a flare nut into the pipe, and flare the pipe.

Outer

dia.

6,35mm

9,52mm

12,7mm

A (mm) R22

Imperial

Rigid

1,0 ~ 1,5

0,5 ~ 1,0

1,0 ~ 1,5

0,5 ~ 1,0

1,5 ~ 2,0

0,5 ~ 1,1

A (mm) R410A

Imperial

Rigid

1,5 ~ 2,0

1,0 ~ 1,5

1,5 ~ 2,0

1,0 ~ 1,5

Die

Pipe

A

Fig. 8-5-3

<Tightening connection>

Align the centers of the connecting pipes and tighten

the flare nut as far as possible with your fingers.

Then tighten the nut with a spanner and torque

wrench as shown in the figure.

CAUTION

• Do not apply excess torque. Otherwise, the

nut may crack depending on the installation

conditions.

Outer dia.

6,35mm

9,52mm

12,7mm

Tightening touque

N•m (kgf•m)

16 ~ 18 (1,6 ~ 1,8)

30 ~ 42 (3,0 ~ 4,2)

50 ~ 62 (5,0 ~ 6,2)