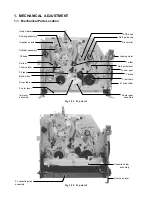

1-4-4. Check by Defective Analyzing Table

If the abnormality causes the mechanism abnormal

condition, presume, confirm and treat the defective

according to the defective analyzing table.

(1) Manual Mechanism Operation (Mode Shift) Method

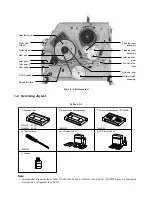

Remove the worm gear holder with tweezers as shown in

Fig.1-4-2, and remove the worm gear.

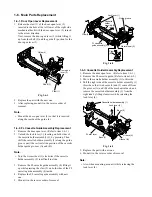

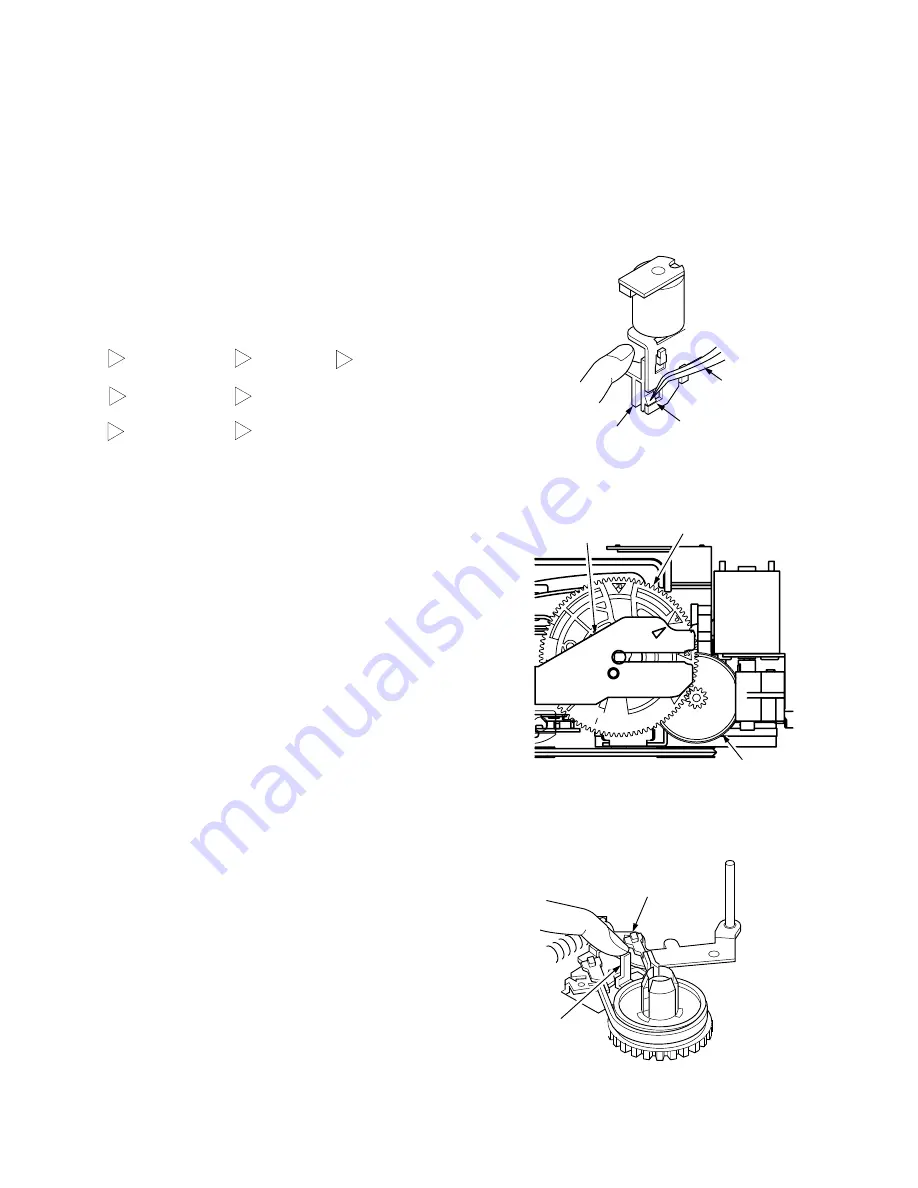

The mode of loading direction can be shifted by turning

the worm wheel clockwise while pushing in the lock

lever R and L of cassette holder manually. At this time,

the mechanism condition is set to each position when

the D mark of FL drive slider and the D mark of FL cam

gear match as shown in Fig. 1-4-3.

Power off

STOP1

STOP2

Review

FF/REW1

Playback

FF/REW2

Check the mechanism condition at the position the

defective occurs.

Notes:

• For REVIEW, STOP2, FF/REW1, turn the worm

wheel to the unloading direction and check the

mechanism condition with each mark matched.

Due to a rattling and deviation of the cam gear, the

practical mark position for stop position carried out

by the cam switch and the mark position may differ.

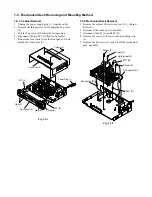

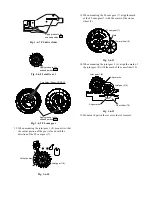

• When operating after removing the cassette holder,

press down the tension drive lever as shown in Fig. 1-

4-4 until the T slider comes AC head position since

the S/T sliders start moving.

(2) Defective Parts Replacement

When a defective occurs due to the defective part (s) and

the part (s) is replaced, take care the following items.

1. Especially as for the mechanical parts requiring the

phase alignment, take care of the part replacement.

E.g.: Assembling mode, phase alignment mark and

etc.

2. As for the part (s) requiring lubricant such as a

specified amount of oil or grease, apply grease or oil

according to the instructions and do not stick grease

or oil to the portions without allowing to stick it

(especially in removal and assembly).

(3) Check after Treating the Defective

After treating the defective unit (especially replacing a

defective part and/or aligning a part), first check the

mechanism operation manually and confirm that no

problem occurs, and then mount the mechanical deck on

the VCR, turn the power ON and check the mechanism

operation.

Note:

• After replacing the defective parts according to the

procedure of the treatment method for the damage

and phase mismatch of mechanical part, check the

operation of the mechanism again, since the same (or

similar) defective problem may occur due to other

serious cause (in mechanism or electrical circuit)

when performing the actual total check with turning

the power on.

Fig. 1-4-4

Worm wheel

FL cam gear

FL drive slider

Fig. 1-4-3 Position mark (Playback position)

Fig. 1-4-2

Tension lever

Tension drive

lever

Push downward.

Worm gear holder

Push claw downward.

Tweezers

I

P

FR1

R

S1

S2

FR2