– 11 –

4

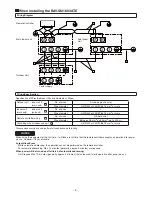

PIPING HEAT INSULATION

Heat insulation was produced locally.

Be certain to heat insulate the piping both on the liquid and gas sides.

• Use heat insulating materials for piping higher than 120 degree in heat resistance.

Example: EPT - Ethylene, propylene, terpolymer

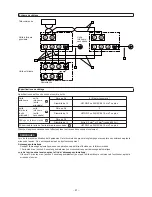

• Heat insulate the branch pipe sections using fitting covers (for tees) more than 10mm in thickness or processing thermal

insulation materials as follows.

(Heat insulation materials for the branch pipes are not supplied as accessories.)

• Seal the branch pipe sections tightly without producing gaps

5

TEST RUN

Be certain to conduct a test run in accordance with the procedures contained in the operating and installation instructions

supplied with the indoor units.

6

DELIVERY TO CUSTOMER

• Make certain to hand over the instruction manual supplied with the indoor units to the customer.

• Deliver the system after thoroughly explaining the contents of the instruction manual.

It is important to explain to the customer in details about simultaneously starting and stopping the two indoor units by

operating one remote controller switch.

Heat insulated pipe of main piping

Seal seams using foamed urethane or

a similar material

Heat insulated pipe of piping

Heat insulated material

Outside diameter of heat insulated pipe of branch piping

90° notch

100mm or more

Seal with vinyl tape

Cut 90°