28-EN

27-EN

– 14 –

EN

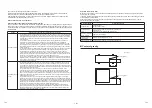

Refrigerant pipe length

Single

Allowable pipe length (m)

Height difference (Indoor-outdoor H) (m)

Total length L

Indoor unit: Upper

Outdoor unit: Lower

30

30

30

Pipe diameter (mm)

Number of bent portions

Gas side

Liquid side

Ø15.9

Ø9.5

10 or less

L

H

Indoor unit

Outdoor unit

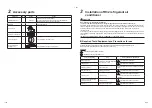

Tightening of connecting part

1

Align the centers of the connecting pipes

and fully tighten the

fl

are nut with your

fi

ngers. Then

fi

x the nut with a wrench as

shown in the

fi

gure and tighten it with a

torque wrench.

Half union or packed valve

Flare nut

Internally

threaded side

Externally

threaded side

Fix with wrench.

Tighten with torque

wrench.

2

As shown in the

fi

gure, be sure to use two

wrenches to loosen or tighten the

fl

are nut

of the valve on the gas side. If you use a

single crescent, the

fl

are nut cannot be

tightened to the required tightening torque.

On the other hand, use a single crescent to

loosen or tighten the

fl

are nut of the valve on the

liquid side.

(Unit: N•m)

Outer dia. of copper pipe

Tightening torque

9.5 mm (dia.)

34 to 42 (3.4 to 4.2 kgf•m)

15.9 mm (dia.)

63 to 77 (6.3 to 7.7 kgf•m)

Loosened

Cap

Tightened

Flare nut

CAUTION

y

Do not put the crescent wrench on the cap or

cover. The valve may break.

y

If applying excessive torque, the nut may break

according to some installation conditions.

Incorrect

Cap

Flare nut

• After the installation work, be sure to check for gas

leaks of the pipe connections with nitrogen.

• Therefore, using a torque wrench, tighten the

fl

are

pipe connecting sections that connect the indoor/

outdoor units at the speci

fi

ed tightening torque.

Incomplete connections may cause not only a gas

leak, but also trouble with the refrigeration cycle.

Do not apply refrigerating machine oil to the

fl

ared surface.