No.

Part name

Procedures

Remarks

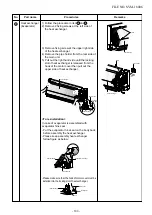

1) Perform work of item 1 of

1

and 1 of

2

.

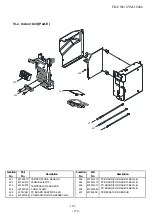

2) Remove the flange nut fixing the fan motor

and the propeller fan.

•

Flange nut is loosened by turning

clockwise.

(To tighten the flange nut, turn counter-

clockwise.)

3) Remove the propeller fan.

4) Disconnect the connector for the fan motor

from the inverter.

5) Remove the fixing screws (4 pcs.) holding

the fan motor by hand so that it does not

fall.

6) Cut the motor lead at the point which is

100 mm apart from the connector toward

the fan.

7) Use the connector used for the inverter,

and pinch the lead wires using the closed

end splice.

Fan motor

Compressor

„

…

100

Fan motor

Propeller fan

Flange nut

Closed end

splice

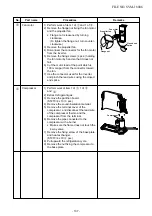

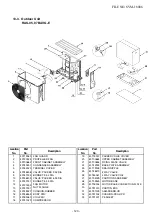

1)

Perform work of item 1 of

1

, 1 of

2

and

ƒ

.

2)

Extract refrigerant gas.

3)

Remove the partition board.

(ST

2

T

∅

4 x 10

s

3 pcs.)

4)

Remove the sound-insulation material.

5)

Remove the terminal cover of the

compressor, and disconnect the lead wire

of the compressor thermo and the

compressor from the terminal.

6)

Remove the pipe connected to the

compressor with a burner.

•

Make sure the flame does not touch the

4 way valve.

7)

Remove the fixing screw of the base plate

and heat exchanger.

(ST

2

T

∅

4 x 10

s

2 pcs.)

8)

Pull upward the refrigeration cycle.

9)

Remove the nut fixing the compressor to

the base plate.

Compressor

FILE NO. SVM-18006

- 107 -

Содержание RAS-B05BKVG-E

Страница 19: ...4 2 Outdoor Unit RAS 05 07BAVG E RAS 10 13BAVG E1 C L C L 280 400 Unit mm FILE NO SVM 18006 19 ...

Страница 22: ...RAS B16BKVG E RAS 16BAVG E FILE NO SVM 18006 22 ...

Страница 126: ...144 9 MOO 5 BANGKADI INDUSTRIAL PARK TIVANON ROAD TAMBOL BANGKADI AMPHUR MUANG PATHUMTHANI 12000 THAILAND ...