11

Installation Manual

Outdoor Unit

3. Turn on the circuit breaker to supply electricity.

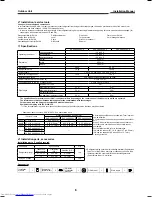

In the initial LED display status, D805 is lighted as below.

: ON,

: OFF, : Rapid Flashing (5 times/sec.),

: Slow Flashing (1 time/sec.)

D800

D801

D802

D803

D804

D805

Start running all the indoor units connected to the outdoor unit in the

cooling mode.

(The indoor unit in the room that doesn’t operate the cooling mode cannot

be checked.)

4. After 5 minutes, hold down SW01 for at least 5 seconds, and check that

D800 is lighted and D804 light is

fl

ashing ( 1 time/sec.).

D800

D801

D802

D803

D804

D805

5. Press the SW01 4 times until the LED is displayed as below.

D800

D801

D802

D803

D804

D805

6. Press SW02 for 1 times. Then D805 light is flashing (5 times/sec.).

D800

D801

D802

D803

D804

D805

7. Hold down SW02 for at least 5 seconds. Then the wiring/piping check

starts automatically. (The LED display is lighted for a moment.)

D800

D801

D802

D803

D804

D805

• If no problems are detected, the checking operation returns to the

normal operation automatically. The LED is displayed as below.

D800

D801

D802

D803

D804

D805

8. The below is displayed when the error is detected.

(* Repetition of 3 sec ON / 0.5 sec OFF)

D800

D801

D802

D803

D804

D805

*

*

*

*

*

Press the SW01 3 times until the LED is displayed as below, to check the

room judged as error.

D800

D801

D802

D803

D804

D805

Incorrect wiring/piping can be checked by pressing SW02. The LED is

displayed as below. Turn off the circuit breaker, then check wiring/piping

again.

Check result

D800 D801 D802 D803 D804 D805

Description

Normal operation (no error)

Trouble in unit A

Trouble in unit B

Trouble in unit C

Trouble in unit A and B

Trouble in unit A and C

Trouble in unit B and C

Trouble in unit A, B and C

• The D800 LED represents unit A.

• The D801 LED represents unit B.

• The D802 LED represents unit C.

9. When you want to start over the operation of the SW01 and SW02, press

the SW01 and the SW02 at the same time for 5 sec. (The procedure will

set back to step 3.) However, do not execute the operation during the

check. If by any chance the check is stopped by the operation, start over

the check after turning off the power once.

10. Notes

• It sometimes takes about 30 minutes maximum for the check.

• During the check, the compressor and the fan of the outdoor/indoor unit

repeat ON/OFF.

• You cannot check wiring/piping when the external temperature is 5°C

or less. Also, there is a possibility to misjudge if the indoor temperature

becomes too low by cooling operation. In that case, execute the cooling

operation for per room and check if the connection is normal.

■

Gas Leak Inspection

Refer to the “ Gas Leak Inspection” on page 9.

■

Test run

1. If you perform the test run in summer, start running in the cooling mode

fi

rst

to decrease the temperature of the room, then run in the heating mode.

(Heating mode: Set the temperature to 30°C.)

• If you perform the test run in winter, start running in the heating mode

fi

rst

to increase the temperature of the room, then run in the cooling mode.

(Cooling mode: Set the temperature to 17°C.)

2. For the test run, be sure to satisfy the following conditions below:

- Perform the test run for each indoor unit respectively.

- Perform the test run for about 10 minutes in both the cooling mode and

the heating mode.

• You can perform the test run in the cooling/heating mode by utilizing the

thermo sensor of the indoor unit.

Cooling mode: Warm the thermo sensor using an appliance such as a

hair dryer.

Heating mode: Put a cold towel on the thermo sensor.

■

Instructions for the Customers

• Explain to the customers the proper operation procedure and let them

operate the air conditioner along with the supplied instruction manual.

• When multiple indoor units are connected to the outdoor unit, the cooling

mode and the heating mode are not available at the same time.

When multiple indoor units are running at the same time, the operation mode

of the unit which starts running

fi

rst is applied to the other units.

• When you start running the indoor unit or change the operation mode, the

unit starts running after 3 minutes. This is due to the protection function of

the unit, not a malfunction.

• When the external temperature becomes low, the pre-heating of the

compressor starts to protect it. Keep the circuit breaker on for use.

The electricity consumption during pre-heating is about 30 W.

If the circuit breaker is turned off, the indoor unit may not start running for

about 10 minutes or more.

• Electronic expansion valves are used for the outdoor unit.

When you turn on the power, the outdoor unit starts clattering every 1 or

2 months. This clattering is not a malfunction, but occurs when the unit is

returning to the default setting for optimised control.

• While an indoor unit is running in the heating mode, the outdoor unit supplies

refrigerant to the other indoor units which are not running.

Therefore, noise may come from the other indoor units or the exterior of

them may become warm.

1116691099_(01) EN.indd 11

1116691099_(01) EN.indd 11

9/22/15 5:59 PM

9/22/15 5:59 PM