88

(

∗

)

¡

: Goes on,

¥

: Flashes,

l

: Goes off

A (Alternate)

: Flashing condition is alternate when there are two flashing LED.

S (Simultaneously) : Two LED flash simultaneously when there are two flashing LED.

Outdoor 7-segment

Auxiliary code

H04

—

H06

—

H07

—

01: TK1 sensor error

H08

02: TK2 sensor error

03: TK3 sensor error

04: TK4 sensor error

H14

—

01: TK1 oil circuit system error

H16

02: TK2 oil circuit system error

03: TK3 oil circuit system error

04: TK4 oil circuit system error

L04

—

L06

No. of priority indoor units

(Individual display: [L05/L06])

L08

—

L10

—

L18

—

L28

—

01: A3-IPDU1 error

02: A3-IPDU2 error

03: A3-IPDU1, 2 error

L29

04: Fan IPDU error

05: A3-IPDU1 + fan IPDU error

06: A3-IPDU2 + fan IPDU error

07: All IPDU error

L30

Detected indoor unit No.

P03

—

P05

01: Detection of open phase

02: Negative phase error

P07

01: Compressor 1 side

02: Compressor 2 side

P10

Detected indoor unit No.

P13

—

P15

01: TS condition

02: TD condition

P17

—

P19

Detected outdoor unit No.

P20

—

TCC-LINK central

& remote controller

H04

H06

H07

H08

H14

H16

L04

L05

L06

(L08)

L10

L18

L28

L29

(L30)

P03

P05

P07

(P10)

P13

P15

P17

P19

P20

AI-NET central

(Network adapter use)

44

20

d7

d4

44

d7

96

96

96

(99)

88

8A

46

CF

(b6)

1E

AF

1C

(Ob)

47

AE

bb

O8

22

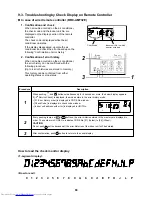

Sensor lamp display

Block display (

∗

)

Operation Timer Ready Flash

l

¥

l

l

¥

l

l

¥

l

l

¥

l

l

¥

l

l

¥

l

¥

¡

¥

S

¥

l

¥

S

¥

l

¥

S

¥

l

¥

S

¥

¡

¥

S

¥

¡

¥

S

¥

¡

¥

S

¥

¡

¥

S

¥

¡

¥

S

¥

l

¥

A

¥

l

¥

A

¥

l

¥

A

l

¥ ¥

A

l

¥ ¥

A

¥

l

¥

A

¥

l

¥

A

¥

l

¥

A

¥

l

¥

A

Main defective position

Compressor1 case thermo operation

Low pressure protective operation

Oil face drop detection protection

Error of temp. sensor (TK1 to 4)

for oil face detection

Compressor2 case thermo operation

Oil face detection circuit system

error

Duplicated outdoor line address

Duplicated priority indoor units

(Displayed in the priority indoor)

Duplicated priority indoor units

(Displayed in except priority indoor)

Unset indoor group address

Unset outdoor capacity

Flow selector unit system error

No. of connected outdoor units over

No. of IPDU units’ error

External error input in indoor unit

(Interlock)

Outdoor discharge (TD1) temp. error

Detection of open phase/Negative

phase error

Heat sink overheat error

There is outdoor unit with detection

of overflow

Outdoor liquid back detection error

Gas leak detection

Outdoor discharge (TD2) temp. error

4-way valve inverse error

High pressure protective operation

Description

When case thermo of compressor 1 performed protective operation

Protective detection operation by low pressure (Ps) sensor

Protective detection operation by temp. sensor (TK1 to 4) for oil face detection

When open/short of temp. sensor (TK1 to 4) for oil face detection was detected

Case thermo of compressor2 performed protective operation.

After start of compressor operation, the temp. variation of temp. sensor

(TK1 to 4) for oil face detection was not detected.

Duplicated setting of line address against outdoor units in different refrigerant

lines

When there were multiple priority indoor units (against priority indoor unit)

When there were multiple priority indoor units (against not priority indoor unit)

There was indoor unit that indoor group address was not set

(Detected at indoor unit side also)

When capacity of outdoor unit was not set (Replace service P.C. board.)

COOL/HEAT cycle error due to mispiping was detected.

No. of connected outdoor units was over 4.

When No. of IPDU (P.C. board) was little in the inverter box

There was indoor unit which stopped abnormally due to external error input in

1 line. (ß Indoor unit detected.)

When high temp. error was detected by discharge temp. sensor (TD1)

Open phase/Negative phase error was detected when power was supplied.

When high temp. error was detected by outdoor IGBT incorporated temp.

sensor (TH)

There was indoor unit which stopped abnormally due to detection of overflow

in 1 line. (ß Indoor unit detected.)

When error was judged as liquid back operation from the refrigerant cycle status

The outdoor suction temp. sensor (TS1) detected high temperature

continuously and repeatedly over the standard value.

Discharge temp. sensor (TD2) detected high temp. error.

Error of refrigerant cycle error was detected during heating operation.

High pressure (Pd) sensor detected value over the standard value.

Check code display