167

START

* This flowchart is the standard for replacing compressors.

Each case must be considered on individual circumstances.

Replace the compressors based on the following conditions

of judgement.

1. Oil of 1900 cc is charged in a compressor for service.

2. The amount of oil is 1900 cc in an outdoor unit at shipment.

3. When a compressor is removed, it usually contains

800 to 1500 cc of oil.

Turn off power to the troubled outdoor unit.

Recover refrigerant from outdoor unit,

using a suitable device.

Remove the troubled compressor.

Measure oil amount in the troubled compressor.

Adjust oil amount based upon the measured oil amount.

Install compressor.

Check for leakage in the malfunctioning outdoor unit.

Vacuum the malfunctioning outdoor unit.

Charge the refrigerant.

END

13. REPLACING COMPRESSOR

13-1. Compressor Replacing Procedure (Outline)

WARNING

Never recover the refrigerant into outdoor unit.

Be sure to use a refrigerant recovery device for refrigerant recovery for reinstallation or repair work.

Recovery into the outdoor unit is unavailable; otherwise a serious accident such as rupture or ingury could

occur.

NOTE) Full opening operation of PMV by CN30

short-circuiting rwill return to fully closed

after 2 minutes have passed.

To continue full-opening status, turn off

power to the outdoor unit within 2 minutes.

13-2. Replacing Compressor

Vacuuming

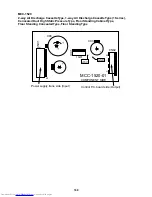

In case of single outdoor system

• Connect vacuum pump to the valve charge ports on

the liquid and gas then vacuum.

• Vacuum until the vacuum low-pressure gauge indicates 1 (mmHg).

Note)

• Before vacuuming, open PMV fully. Vacuuming of the outdoor heat exchanger will not occur if PMV is

closed.

Full opening of PMV

• Turn on the power

to the outdoor unit.

• Confirm that Bit 1 on SW12 is OFF.

• Short CN30 on I/F P.C. board on the outdoor unit.

• Turn off the power to the outdoor unit within 2 minutes of short-circuiting.