EN

EN

FR

IT

DE

PT

PL

CZ

RU

CR

HU

TR

NL

GR

SV

FI

NO

DK

RO

BG

EE

LV

SK

SI

11

Air to water heat pump

operating conditions

OTHERS

OTHERS

Gas Leak Test

Finishing

After the refrigerant pipe, Hydro / Outdoor connecting wires have been

connected, cover them with

fi

nishing tape and clamp them to the wall with

off-the-shelf support brackets or their equivalent.

Keep the power wires and Hydro / outdoor connecting wires off the valve on

the gas side or pipes that have no heat insulator.

Earthing

Connect the earth wire properly following applicable technical standards.

Connecting the earth wire is essential to preventing electric shock and to

reducing noise and electrical charges on the outdoor unit surface due to the

high-frequency wave generated by the frequency converter (inverter) in the

outdoor unit.

If you touch the charged outdoor unit without an earth wire, you may

experience an electric shock.

Test run

Annual maintenance

• Turn on the leakage breaker at least 12 hours before starting a test run to

protect the compressor during startup.

• Check the following before starting a test run:

•

That all pipes are connected securely without leaks.

• That the valve is open.

If the compressor is operated with the valve closed, the outdoor unit will

become overpressurized, which may damage the compressor or other

components.

If there is a leak at a connection, air can be sucked in and the internal

pressure further increases, which may cause a burst or injury.

• Operate the air to water heat pump in the correct procedure as speci

fi

ed

in the Owner’s Manual.

Please refer to the Hydro unit installation manual for the detail of the test

run.

• For an air to water heat pump system that is operated on a regular basis,

cleaning and maintenance of the Hydro / outdoor units are strongly

recommended.

As a general rule, if an Hydro unit is operated for about 8 hours daily, the

Hydro / outdoor units will need to be cleaned at least once every

3 months.

This cleaning and maintenance should be carried out by a quali

fi

ed

service person.

Failure to clean the Hydro / outdoor units regularly will result in poor

performance, icing, water leaking and even compressor failure.

For proper performance, operate the air to water heat pump under the

following temperature conditions:

Cooling operation

10 °C to 43 °C

Heating operation

-20 °C to 25 °C

Hot water operation

-20 °C to 43 °C*

If air to water heat pump is used outside of the above conditions, safety

protection may work.

* Heater operation in more than 35 °C

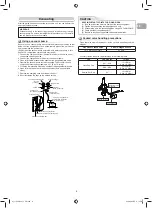

Check places for

the hydro unit.

Check places for

the outdoor unit.

• Check the

fl

are nut connections for the gas leak with a gas leak detector or

soap water.

01_1120551201-1 EN.indd 11

01_1120551201-1 EN.indd 11

5/18/2560 BE 3:12 PM

5/18/2560 BE 3:12 PM

Содержание HWS-455H-E

Страница 1: ...Outdoor unit HWS 455H E AIR TO WATER HEAT PUMP INSTALLATION MANUAL ENGLISH ...

Страница 14: ......