CONTENTS

[1]

GENERAL

1. Major functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2]

SPECIFICATIONS

1. Basic Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. Operation specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3. Copy performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

4. GDI Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

5. Scan function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

[3]

CONSUMABLE PARTS

1. Supply system table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

A. North America/Brazil/Central and South America/Asia/

Saudi Arabia Subsidiary . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

2. Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3. Production control number (lot No.) identification . . . . . . . . . . 3-2

4. Toner cartridge replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

[4]

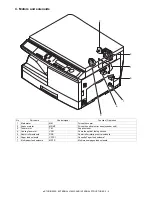

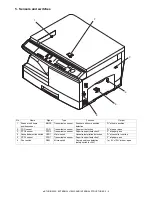

EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. Internal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

3. Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4. Motors and solenoids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

5. Sensors and switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

6. PWB unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

7. Cross sectional view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

[5]

UNPACKING AND INSTALLATION

1. Copier installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2. Cautions on handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

3. Checking packed components and accessories . . . . . . . . . . . 5-1

4. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5. Removing protective packing materials . . . . . . . . . . . . . . . . . . 5-2

6. Developer unit installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

7. Toner cartridge installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

8. Loading paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

9. Power to copier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

10. Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

11. Connecting the interface cable . . . . . . . . . . . . . . . . . . . . . . . . 5-5

12. Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

A. USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

13. Moving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

14. Scanner moisture-proof parts . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

A. Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

B. Precautions at installation. . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

C. Attachment method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

[6]

COPY PROCESS

1. Functional diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

2. Outline of print process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

3. Actual print process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

[7]

OPERATIONAL DESCRIPTIONS

1. Outline of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. Scanner section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

A. Scanner unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

B. Optical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

C. Drive system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

3. Laser unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

A. Basic structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

B. Laser beam path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

C. Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

4. Fuser section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

A. General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

5. Paper feed section and paper transport section . . . . . . . . . . . 7-4

A. Paper transport path and general operations . . . . . . . . . . . 7-4

[8]

DISASSEMBLY AND ASSEMBLY

1. High voltage section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

A. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

B. Drum replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

C. Disassembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

D. Assembly procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

E. Charger wire cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

F. Charger wire replacement . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

2. Operation panel section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

A. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

B. Disassembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

C. Assembly procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

3. Optical section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

A. List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

B. Disassembly procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

4. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

A. List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

B. Disassembly procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

5. Tray paper feed/transport section . . . . . . . . . . . . . . . . . . . . . 8-10

A. List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

B. Disassembly procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

6. Manual paper feed section . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

A. List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

B. Disassembly procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

D. Pressure plate holder attachment . . . . . . . . . . . . . . . . . . . 8-17

7. Rear frame section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

A. List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

B. Disassembly procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

8

Power section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

A. List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

B. Disassembly procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

[9]

ADJUSTMENTS

1. Optical section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

A. Copy magnification ratio adjustment . . . . . . . . . . . . . . . . . . 9-1

B. Image position adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

2. Copy density adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

A. Copy density adjustment timing . . . . . . . . . . . . . . . . . . . . . 9-4

B. Note for copy density adjustment . . . . . . . . . . . . . . . . . . . . 9-4

C. Necessary tool for copy density adjustment . . . . . . . . . . . . 9-4

D. Features of copy density adjustment . . . . . . . . . . . . . . . . . 9-4

E. Copy density adjustment procedure . . . . . . . . . . . . . . . . . . 9-4

3. High voltage adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

A. Main charger (Grid bias) . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

B. DV bias check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

4. Automatic black level correction. . . . . . . . . . . . . . . . . . . . . . . . 9-6

[10] SIMULATION, TROUBLE CODES

1. Entering the simulation mode. . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. List of simulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

3. Contents of simulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

4. Trouble codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-17

A. Trouble codes list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-17

B. Details of trouble codes. . . . . . . . . . . . . . . . . . . . . . . . . . 10-17

[11] MAINTENANCE

1. Maintenance table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

2. Maintenance display system . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] USER PROGRAMS

1. Functions that can be set with user programs . . . . . . . . . . . . 12-1

2. Toner save mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

3. User programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

[13] ELECTRICAL SECTION

1. Block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

A. Overall block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

2. Actual wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

A. MCU PWB (1/3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

B. ADF unit (2/3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-3

C. 2nd cassette unit (3/3). . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-3

3. Signal name list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-4

4. Circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-6

A. MCU PWB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-6

B. OPE PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-18

[14] FIRMWARE DOWNLOAD PROCEDURES

1. Initial setting

(Serial number setting procedures) . . . . . . . . . . . . . . . . . . . . 14-1

2. Download procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

3. Version acquisition procedures . . . . . . . . . . . . . . . . . . . . . . . 14-3

4. EEPROM data acquisition procedure. . . . . . . . . . . . . . . . . . . 14-4

5. Installing procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-5