– 11 –

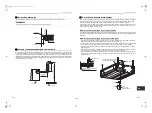

Fan characteristics

◆

No filter

AP007, AP009

AP012

AP015

AP018

200 220 240 260 280 300 320 340 360 380 400

0.000

0.050

0.100

0.150

0.200

0.250

Standerd air flow rate: 317.8 (cfm)

Dotted line: Upper limit of external static pressure

Lower limit of external static pressure

Ex

te

rn

al

st

at

ic

pre

ss

ure (

in.

W

G

)

Air flow rate (cfm)

Ai

r fl

ow

r

a

te l

o

w

e

r l

im

it

Ai

r fl

ow rate upp

er l

imi

t

High (0.20 in.WG)

High (0.14 in.WG)

High (0.08 in.WG)

Low (0.20 in.WG)

Low (0.14 in.WG)

Low (0.80 in.WG)

220 240 260 280 300 320 340 360 380

420

400

0.000

0.050

0.100

0.150

0.200

0.250

Standerd air flow rate: 353.1 (cfm)

Dotted line: Upper limit of external static pressure

Lower limit of external static pressure

Ex

te

rn

al

st

at

ic

pre

ss

ure (

in.

W

G

)

Air flow rate (cfm)

Ai

r fl

ow

r

a

te l

o

w

e

r l

im

it

Ai

r fl

ow rate upp

er l

imi

t

High (0.20 in.WG)

High (0.14 in.WG)

High (0.08 in.WG)

Low (0.20 in.WG)

Low (0.14 in.WG)

Low (0.80 in.WG)

260 280 300 320 340 360 380

480

400 420 440 460

0.000

0.050

0.100

0.150

0.200

0.250

Standerd air flow rate: 406.1 (cfm)

Dotted line: Upper limit of external static pressure

Lower limit of external static pressure

Ex

te

rn

al

st

at

ic

pre

ssu

re

(

in.

W

G

)

Air flow rate (cfm)

Ai

r f

low rat

e

lower

li

mi

t

Ai

r fl

ow rate

upper l

imi

t

High (0.20 in.WG)

High (0.14 in.WG)

High (0.08 in.WG)

Low (0.20 in.WG)

Low (0.14 in.WG)

Low (0.80 in.WG)

300

480 500 520

320 340 360 380

540

400 420 440 460

0.000

0.050

0.100

0.150

0.200

0.250

Standerd air flow rate: 459.0 (cfm)

Dotted line: Upper limit of external static pressure

Lower limit of external static pressure

Ex

te

rn

al

st

at

ic

pre

ssu

re

(

in.

W

G

)

Air flow rate (cfm)

Ai

r f

low rat

e

lower

li

mi

t

Ai

r fl

ow rate

upper l

imi

t

High (0.20 in.WG)

High (0.14 in.WG)

High (0.08 in.WG)

Low (0.20 in.WG)

Low (0.14 in.WG)

Low (0.80 in.WG)

7

Refrigerant piping

CAUTION

When the refrigerant pipe is long, provide support

brackets at intervals of 8’2” to 9’10” (2.5 to 3 m) to clamp

the refrigerant pipe. Otherwise, abnormal sound may be

generated.

Use the flare nut attached with the indoor unit or R410A

flare nut.

Permissible piping length and

height difference

They vary depending on the outdoor unit. For details,

refer to the Installation Manual attached to the outdoor

unit.

Pipe size

Unit: in (mm)

Connecting refrigerant piping

Flaring

1

Cut the pipe with a pipe cutter.

Remove burrs completely. (Remaining burrs may

cause gas leakage.)

2

Insert a flare nut into the pipe, and flare the

pipe.

Use the flare nut provided with the unit or the one

used for the R410A refrigerant. The flaring

dimensions for R410A are different from the ones

used for the conventional R22 refrigerant. A new

flare tool manufactured for use with the R410A

refrigerant is recommended, but the conventional

tool can still be used if the projection margin of the

copper pipe is adjusted to be as shown in the

following table.

Projection margin in flaring: B

Unit: in (mm)

Flaring diameter size: A

Unit: in (mm)

* In case of flaring for R410A with the conventional

flare tool, pull it out approx. 0.02” (0.5 mm) more than

that for R22 to adjust to the specified flare size. The

copper pipe gauge is useful for adjusting projection

margin size.

• The sealed gas was sealed at the atmospheric

pressure so when the flare nut is removed, there will

no “whooshing” sound: This is normal and is not

indicative of trouble.

• Use two wrenches to connect the indoor unit pipe.

Model MMD-

Pipe size

Gas side

Liquid side

AP007 to AP012

3/8” (9.5)

1/4” (6.4)

AP015 to AP018

1/2” (12.7)

1/4” (6.4)

Outer dia. of

copper pipe

R410A tool used

Conventional

tool used

1/4” to 1/2”

(6.4 to 12.7)

0 to 0.02”

(0 to 0.5)

0.04” to 0.06”

(1.0 to 1.5)

Outer dia. of copper pipe

A

+0

–0.02” (0.4)

1/4” (6.4)

0.36” (9.1)

3/8” (9.5)

0.52” (13.2)

1/2” (12.7)

0.65” (16.6)

B

A

Work using double spanner

21-EN

22-EN

+00EH99885401.book Page 11 Friday, March 2, 2012 11:01 AM