9

Outdoor Unit

Installation Manual

5

Installation of outdoor unit

Installation Location

• A place which can bear the weight of the outdoor unit and does not cause

an increase in noise level and vibration.

• A place where the operation noise and air discharge do not disturb

neighbours.

• A place which is not exposed to strong wind.

• A place free of combustible gas.

• A place which does not block a passageway.

• A place where the drain water does not cause any problems.

• A place where there are no obstructions near its air intake or air discharge.

Installation in the following places may result in trouble:

• A place with a lot of machine oil.

• A place with saline-rich atmosphere such as a coastal area.

• A place with high level of sul

fi

de gas.

• A place where high-frequency waves are likely to be generated, such as

from audio equipment, welders, or medical equipment.

Do not install the unit in such places.

CAUTION

When the outdoor unit is installed in a

place where the drain water might cause

any problems, Seal the water leakage

point tighty using a silicone adhesive or

caulking compound.

Precautions for Installation

• When the outdoor unit is to be installed in an elevated position, be sure to

secure its feet.

• If the outdoor unit is to be mounted on a wall, make sure the base plate

supporting it is sturdy enough.

• The base plate should be designed and manufactured to maintain its

strength over a long period of time, and suf

fi

cient consideration should be

given to ensure that the outdoor unit will not fall.

• When the outdoor unit is installed in a place that is always exposed to

strong wind such as a coastal area or on a high story of a building, secure

the normal fan operation using a duct or a wind shield.

• Especially in windy areas, install the unit in such a way as to prevent the

admission of wind.

• When the outdoor unit is to be mounted high on a wall, take particular care

to ensure that parts do not fall, and that the installer is protected.

• When doing installation work at ground level, it is usual to make wiring and

pipe connections to the indoor units

fi

rst, and then to make connections to

the outdoor units.

However, if outdoor work is dif

fi

cult, you can change the procedure.

For example, by making adjustments to the wiring and piping lengths on

the inside (rather than the outside).

• When using an air conditioner under low outside temperature conditions

(Outside temp: -5 °C or lower) In COOL mode, prepare a duct or wind

shield so that it is not affected by the wind.

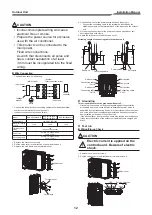

Necessary Space for Installation

If you need to install the outdoor unit in a location where there are some

obstructions or a wall, secure suf

fi

cient space as shown in the

fi

gure below.

The cooling/heating effect may be reduced by 10%.

600 mm or more

100 mm or more

600 mm or more

600 mm or more

100 mm or more

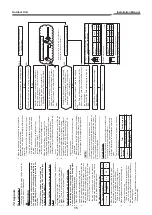

Draining Off the Water from the Outdoor Unit

Install 2 waterproof rubber caps and the drain nipple to drain off the

water from the outdoor unit.

• Seal the knock-out holes and screw/thread areas tightly using a silicon

adhesive or a caulking compound.

• Use a drain pan to apply a centralized drain.

Drain nipple

Water-proo

fi

ng rubber cap

Installation in Regions with Snowfall and Cold Temperatures

Do not use waterproof rubber caps or a drain nipple.

• If you need to install the outdoor unit in a location where there is a

possibility of the drain freezing, pay close attention so that the drain does

not become frozen.

• To protect the outdoor unit from snow, install the outdoor unit on a holding

frame, and attach a snow protection hood and plate.

• Keep the outdoor unit at least 500 mm above the snow accumulation line.

Snow protection plate

Snow protection hood

At least 500 mm

Snow accumulation line

Holding frame

Anchor bolts

Front

Fixing the Outdoor Unit

Fix the outdoor unit using attachment bolts.

• Use 8 mm or 10 mm anchor bolts and nuts.

• Do not allow the attachment bolts to protrude by more than 15 mm.

• Install the outdoor unit at ground level.

• Attach the vibration-proof rubber pads under the

fi

xing legs.

Drain nipple mounting hole

508

600

99

100

Drain hole

15 mm or

less

GOOD

BAD

Absorb vibration

with vibration-proof

rubber pads

If only the end of

the mounting leg

is supported, it

may deform.

Do not support

the outdoor unit

only with the

mounting leg.

Mounting

leg

Foundation

Bottom plate of

outdoor unit

Foundation

Support the bottom surface of the mounting

leg that is in contact with and underneath the

bottom plate of the outdoor unit.

Foundation

351

330

54

Содержание 13340

Страница 17: ......