Fuel System

Maintenance

Under certain conditions, diesel fuel and fuel

vapors are highly flammable and explosive. A

fire or explosion from fuel can burn you and

others and can cause property damage.

•

Use a funnel and fill the fuel tank outdoors,

in an open area, when the engine is off and

is cold. Wipe up any fuel that spills.

•

Do not fill the fuel tank completely full. Add

fuel to the fuel tank until the level is 1/4 to

1/2 in. (6 to 13 mm) below the bottom of

the filler neck. This empty space in the tank

allows the fuel to expand.

•

Never smoke when handling fuel, and stay

away from an open flame or where fuel

fumes may be ignited by a spark.

•

Store fuel in a clean, safety-approved

container and keep the cap in place.

Draining the Fuel Tank

Service Interval:

Every 800 hours

Before storage

Drain and clean the fuel tank if the fuel system becomes

contaminated or if the machine is to be stored for an

extended period. Use clean fuel to flush out the tank.

Checking the Fuel Lines and

Connections

Check the fuel lines and connections every 400 hours

or yearly, whichever comes first. Inspect them for

deterioration, damage, or loose connections.

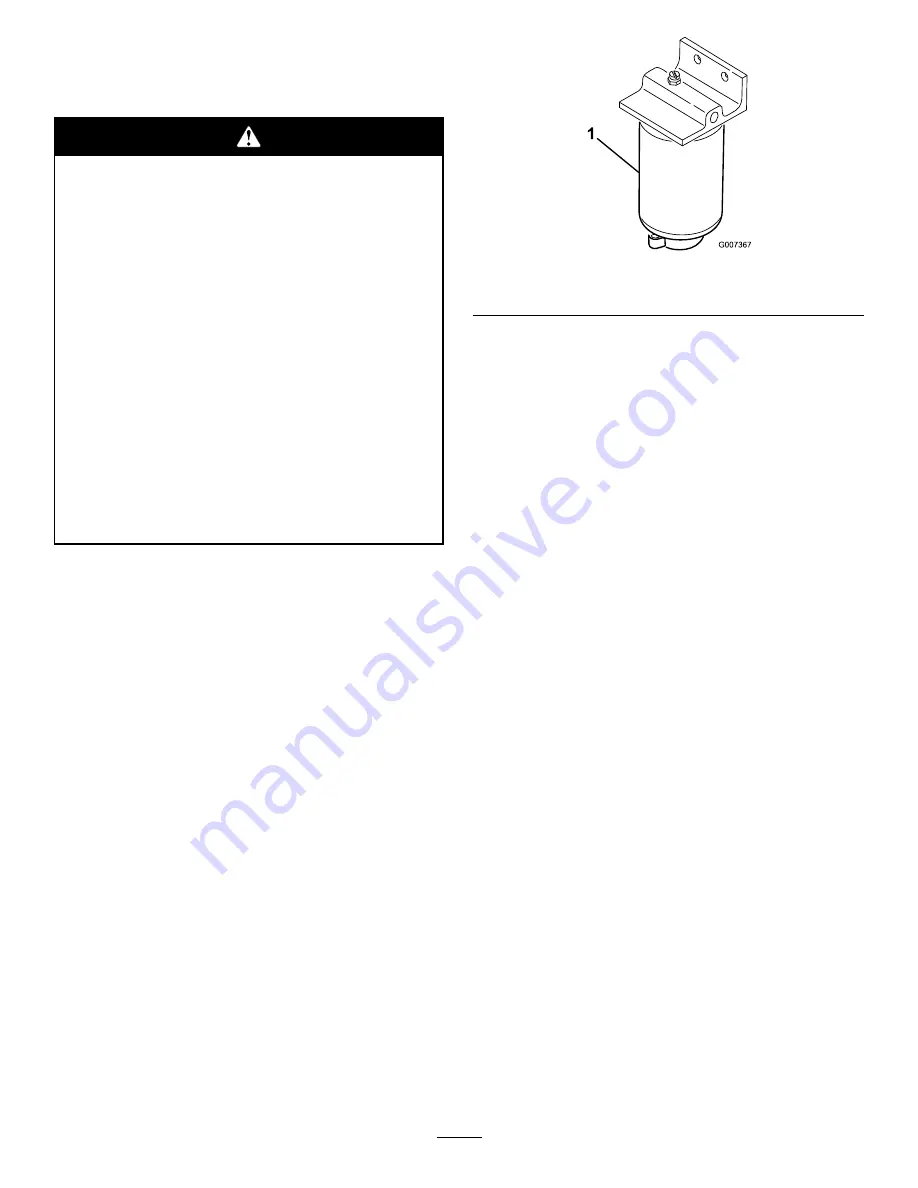

Servicing the Water Separator

Service Interval:

Every 400 hours

Drain water or other contaminants from water separator

(Figure 64) daily. Replace filter canister after every 400

hours of operation.

1. Place a clean container under the fuel filter.

2. Loosen the drain plug on the bottom of the filter

canister.

Figure 64

1.

Water separator filter canister

3. Clean the area where the filter canister mounts.

4. Remove the filter canister and clean the mounting

surface.

5. Lubricate the gasket on the filter canister with clean

oil.

6. Install the filter canister by hand until the gasket

contacts mounting surface, then rotate it an

additional 1/2 turn.

7. Tighten the drain plug on the bottom of the filter

canister.

Fuel Pick-up Tube Screen

The fuel pick-up tube, located inside the fuel tank, is

equipped with a screen to help prevent debris from

entering the fuel system. Remove the fuel pick-up tube

and clean screen as required.

Bleeding Air from the Fuel

Injectors

Note:

This procedure should be used only if the

fuel system has been purged of air through normal

priming procedures and the engine will not start; refer

to Bleeding the Fuel System in , page .

1. Loosen the pipe connection to the No. 1 nozzle and

holder assembly (Figure 65).

45

Содержание Reelmaster 5210

Страница 11: ...114 0429 1 Read the Operator s Manual 11 ...

Страница 56: ...Schematics Hydraulic Schematic Model 5210 5410 Rev A 56 ...

Страница 57: ...Hydraulic Schematic Model 5510 5610 Rev A 57 ...

Страница 58: ...Electrical Schematic Rev 58 ...

Страница 59: ...Notes 59 ...