Checking the Cooling

System

The capacity of the cooling system is approximately

4.6 L (4.9 US qt). Keep the radiator screen clean;

refer to

Cleaning the Radiator Screen (page 44)

.

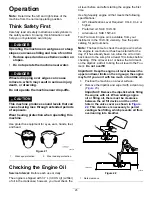

g014613

Figure 25

1.

Wing bolts

3.

Reserve tank

2.

Radiator screen

4.

Radiator fill cap

Fill the cooling system with a 50/50 solution of water

and permanent ethylene glycol antifreeze. Check

the level of the coolant at the beginning of each day

before starting the engine.

CAUTION

If the engine has been running, the

pressurized, hot coolant can escape and

cause burns.

•

Do not open the radiator cap when the

engine is running.

•

Use a rag when opening the radiator cap,

and open the cap slowly to allow steam to

escape.

1.

Park the machine on a level surface.

2.

Check the coolant level (

).

Note:

It should be between the lines on the

reserve tank when the engine is cold.

g008427

Figure 26

1.

Reserve tank

3.

If the coolant is low, remove the reserve tank cap

and add a 50/50 mixture of water and permanent

ethylene glycol antifreeze.

Do not overfill.

4.

Install the reserve-tank cap.

Checking the

Hydraulic-Fluid Level

The hydraulic-fluid reservoir is filled at the factory

with approximately 25.7 L (6.8 US gallons) of high

quality hydraulic fluid. Before operating the machine

each day, check level of the hydraulic fluid in the

white plastic window on the front of the hydraulic-fluid

reservoir (behind the seat on the left side). The fluid

should be between the lines in the window; if not,

add an appropriate fluid as described in the following

sections:

The recommended replacement fluid is as follows:

Toro Premium All Season Hydraulic Fluid

(Available in

5-gallon pails or 55-gallon drums. See parts catalog or

Toro distributor for part numbers.)

Alternate fluids: If the Toro fluid is not available, other

fluids may be used provided they meet all the following

material properties and industry specifications. We

do not recommend the use of synthetic fluid. Consult

with your lubricant distributor to identify a satisfactory

product

Note:

Toro will not assume responsibility for damage

caused by improper substitutions, so use only

products from reputable manufacturers who will stand

behind their recommendation.

High Viscosity Index/Low Pour Point Anti-wear Hydraulic

Fluid, ISO VG 46

Material Properties:

28