23

IMPORTANT:

The oil fill cap/dipstick

must be installed

securely onto the tube at all times when the engine

is operating

. Severe engine damage could result from

a failure to do so.

•

Start the tractor engine and allow it to run for thirty

seconds, then stop the engine and remove the

ignition key.

•

Check the oil level and add oil if necessary.

Do not

overfill the engine crankcase

.

•

Examine the area around the base of the oil fill

tube, the oil filter adapter, and the oil drain valve for

leaks before operating the tractor.

IMPORTANT:

If leaks are present, have your engine

serviced by a

Toro

dealer before operating the tractor.

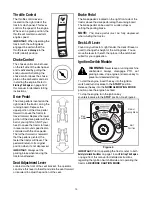

Air Filter

The engine is equipped with a replaceable, high density

paper air cleaner element and an oiled, foam

precleaner. Always examine the air cleaner

before

starting the engine.

Check for a buildup of dirt and

debris around the air cleaner system. Keep this area

clean. Also check for loose or damaged components.

Replace all bent or damaged air cleaner components.

NOTE:

Starting the tractor with loose or damaged air

cleaner components could allow unfiltered air into the

engine causing premature wear and failure.

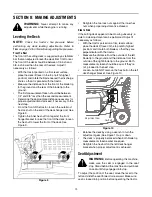

Precleaner

Wash and re-oil the precleaner every

25 hours

of

operation if equipped, (more often under extremely

dusty or dirty conditions).

•

Pivot the air cleaner cover upward and unhook the

wire latch which secures the element in place.

•

Remove the air cleaner element with precleaner.

•

Remove the precleaner.

•

Wash the precleaner in warm water with detergent.

Rinse the precleaner thoroughly until all traces of

detergent are eliminated. Squeeze out excess

water (do not wring). Allow the precleaner to air dry.

•

Saturate the precleaner with new engine oil.

Squeeze out all excess oil.

•

Reinstall the precleaner over the paper element.

•

Reinstall the air cleaner cover.

Service Paper Element

The paper element should be replaced at least every

100 hours

of operation. Replace more frequently if the

tractor is operated under extremely dusty conditions.

To replace the paper element, proceed as follows:

•

Pivot the air cleaner cover upward and unhook the

wire latch which secures the element in place.

•

Remove the air cleaner element with precleaner.

Remove the precleaner from the element and

service as instructed earlier in this section.

IMPORTANT:

Do

not

wash the paper element or use

pressurized air

,

as this will damage the element.

Examine the element and discard if dirt and/or damage

is present.

NOTE:

Handle new elements carefully; do not use if

the sealing surfaces are bent or damaged.

•

If any loose dirt or debris fell on the air cleaner base

when the element was removed, carefully remove it

and wipe the base clean. Be careful that none of it

drops into the intake.

•

Check the air cleaner base. Make sure it is secured

and not damaged. Also check the air cleaner cover

for damage or improper fit. Replace all damaged air

cleaner components.

•

Install the precleaner over the new paper element

and reinstall the element.

•

Lower the wire latch to secure the element in place

and pivot the air cleaner cover downward.

Spark Plugs

Once a season, or after every

100 hours

of operation,

remove the spark plugs, check condition, and reset the

gap or replace with new plugs as necessary.

•

Lift the tractor’s hood and locate the spark plug

wires on either side the engine.

•

Carefully pull the spark plug wire boot off of each

spark plug.

•

Before removing each spark plug, clean the area

around the base of the plug to keep dirt and debris

out of the engine.

•

Using a ratchet with a 5/8-inch spark plug socket,

remove the spark plug and check its condition.

•

Replace the plug if worn, dirty or damaged. Reuse

only after resetting the gap as instructed.

NOTE:

Do not clean the spark plug in a machine

using abrasive grit. Some grit could remain in the spark

plug and enter the engine causing extensive wear and

damage.

Содержание 14AK81RK544

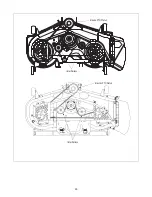

Страница 29: ...29 Idler Pulleys Electric PTO Clutch Idler Pulleys Electric PTO Clutch ...

Страница 34: ...34 NOTES ...